Would you like to get to know Simio better and find out how the software works in practice?

On this page, you will find the latest content from our LinkedIn channel, application examples and short videos that give you a concise insight into the possibilities of Simio.

Whether you are interested in features, application scenarios or news about simulation and APS, you have come to the right place.

Simio in action – videos & demos

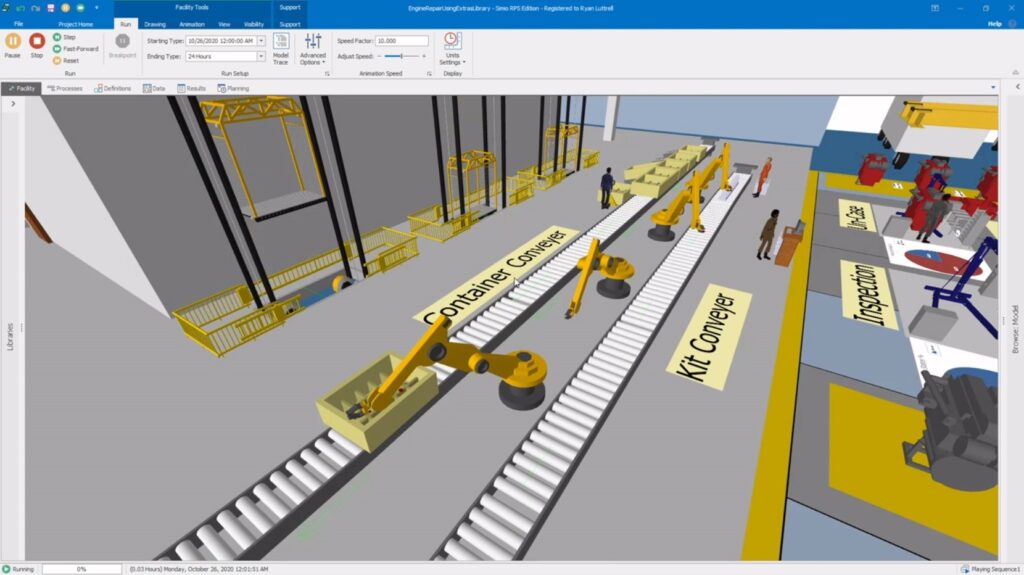

Our videos show typical application examples, modelling with objects and integrated detailed planning (APS) in action. Compact, practical and easy to understand.

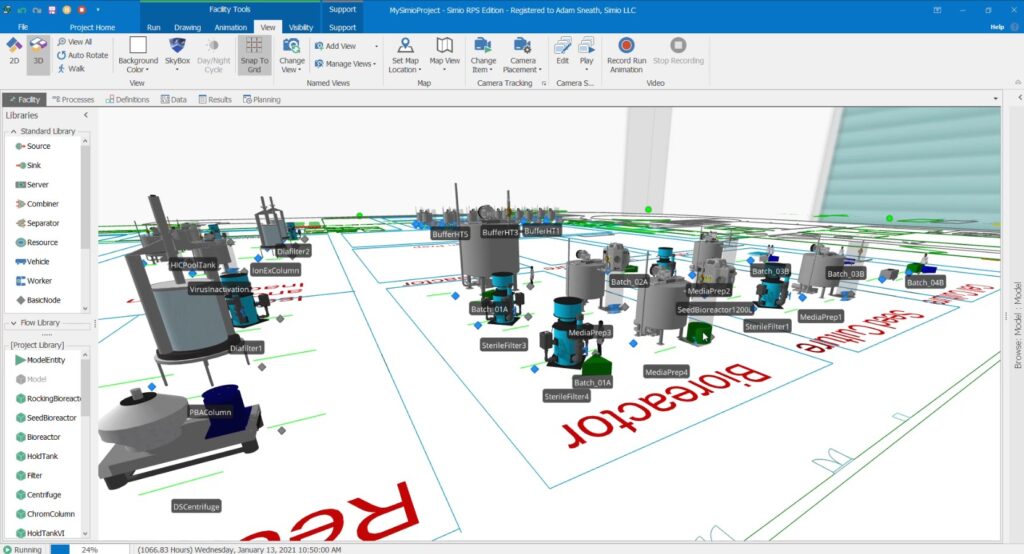

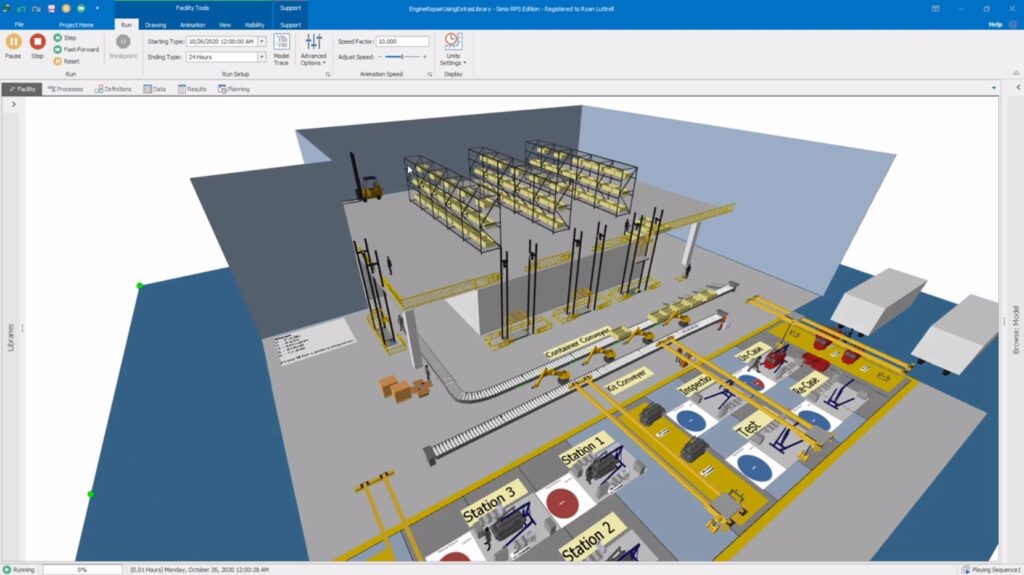

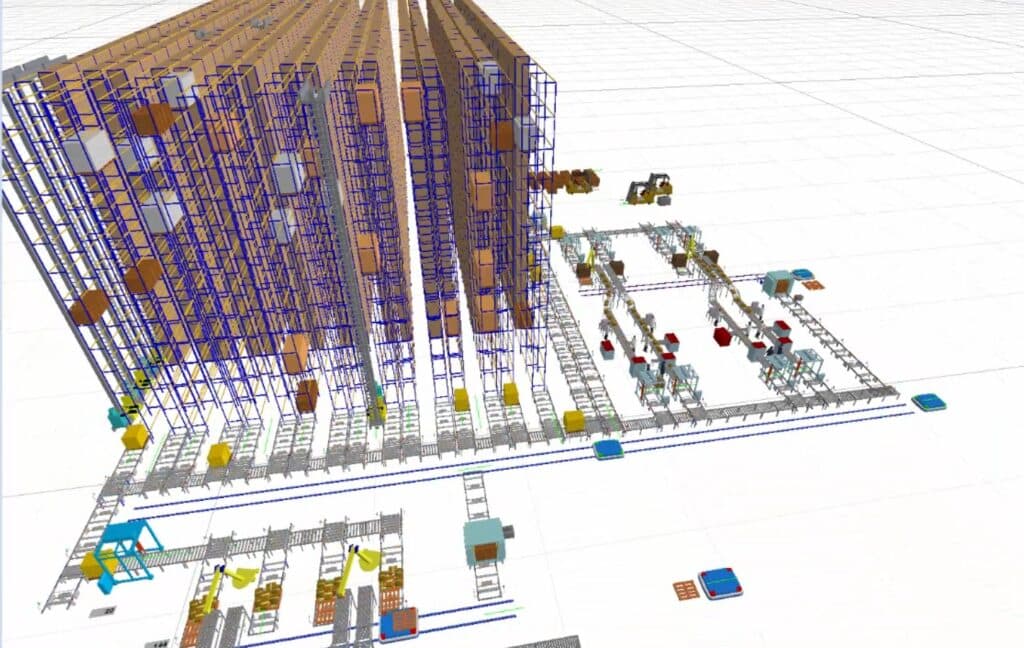

Digital twins with Simio: Simulate complex processes

3D animation of a production line: coffee production with Simio

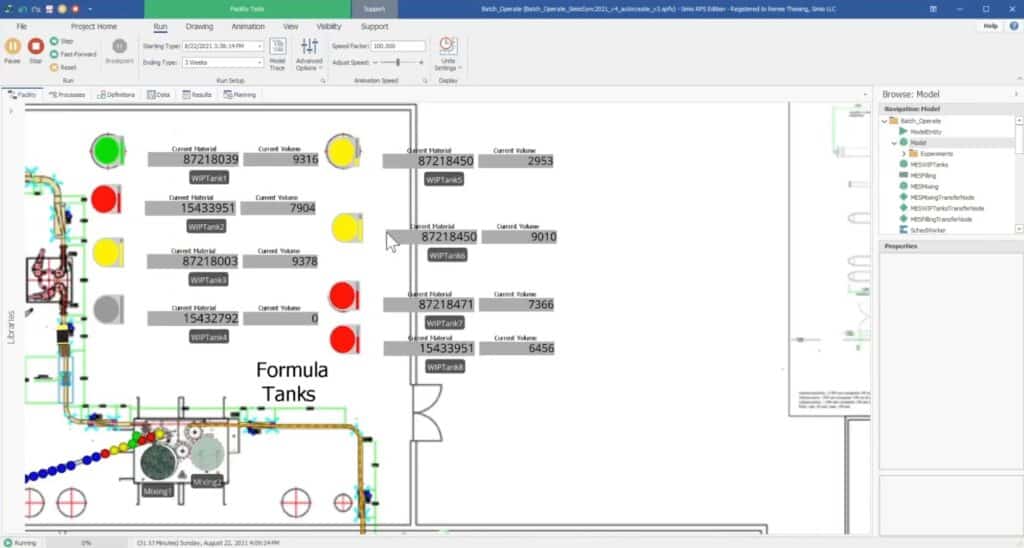

Intelligent production planning with Simio: Adaptive digital twins for efficient scheduling

Posts & expert insights on LinkedIn

We regularly publish posts on LinkedIn about Simio, simulation in the digital factory and practical topics from industry and logistics.

SimioUniversity: Flexible, interactive and customisable

Simio University (SimioU) is a modern learning platform that provides structured, practical knowledge about Simio software – anytime, anywhere.

The advantages at a glance:

- Modular and flexible: The compact Fast Track Essentials course (1 day, approx. 6 hours of video + workshops) offers a quick start.

- In-depth modules: Choose from specific topics such as advanced modelling, experimentation, optimisation or debugging.

- Continuously growing: New content is added regularly to ensure that the latest knowledge is always available.

- Live formats: Simio Learning Bytes offer interactive webinars with Q&A sessions – including recordings for flexible follow-up.

Whether you are a beginner or an experienced simulation user, Simio University supports you in expanding your knowledge in a targeted and efficient manner.

Find out more now and discover the right learning path for you.

How reliable is your production schedule if a machine breaks down tomorrow or an urgent customer order comes in?

Many companies rely on classic planning tools – but these quickly reach their limits when faced with dynamic requirements. Advanced Planning and Scheduling (Hashtag#APS) offers a practical solution here.

Planning vs. reality: Why traditional systems often fail

Traditional planning systems often work with fixed time slots and simplified capacity assumptions. Unforeseen events such as machine breakdowns or delivery delays are often not taken into account, resulting in unrealistic plans. The result: late deliveries, overtime and high inventory levels.

Why SimPlan relies on Simio

As simulation experts with many years of project experience, we closely monitor the market. With Simio, we have specifically expanded our portfolio to include a solution that intelligently combines planning and simulation.

Key factors for us:

- Object-oriented modelling approach

- Combinability of analysis and operational control

- Flexible application options – locally and in the cloud

We see Simio as a useful addition to existing tools – especially for projects involving uncertainty, real-time requirements or an integrative nature.

Interested? Feel free to arrange a web meeting for a product demo.

What happens to our throughput when we introduce new product variants or smaller batch sizes?

Shorter product life cycles and increasing product diversity are challenging many companies. What ran efficiently yesterday is now causing bottlenecks, backlogs and increasing complexity.

The key question is: How do new variants or smaller batch sizes affect productivity – without time-consuming trial and error during ongoing operations?

This is exactly where simulation models come in. They realistically map production systems and show how changes affect throughput times, utilisation, buffers or personnel requirements. This gives you confidence in your actions: instead of gut feelings, you get reliable results. And the ability to quickly compare multiple scenarios before making decisions.

Simulation does not provide a magic formula, but it shows where the limits lie and which adjustments have the greatest leverage.

If you are considering how to make your production future-proof, simulation can be a valuable part of the answer. Please contact us if you have any questions.

Simulation without programming? It’s possible.

Not every simulation project needs its own team of developers.

Simio allows you to build complex models quickly and visually.

Thanks to drag-and-drop operation, you can:

- Model processes

- Create logic

- Adjust parameters – without code

This not only speeds up initial pilot projects, but also makes the method accessible to specialist departments.

Simio – simulation and production planning in one tool

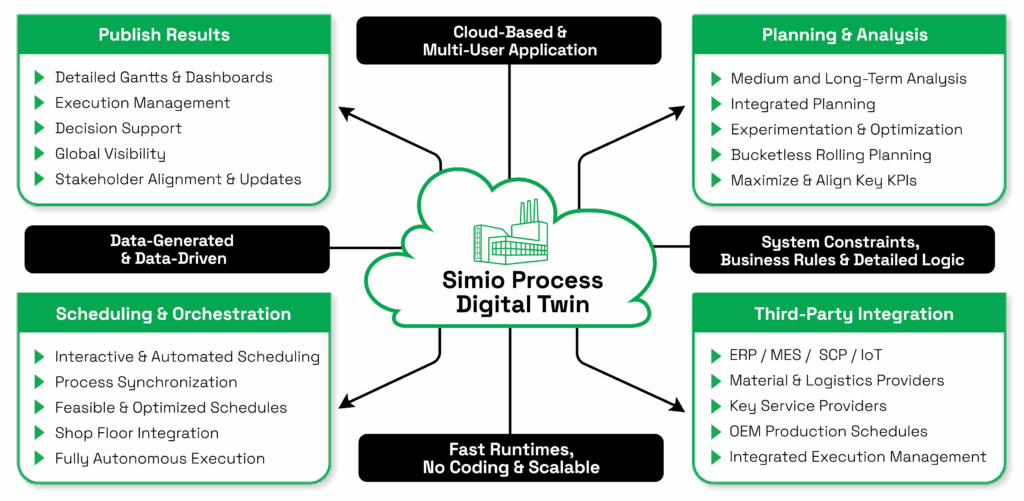

Simio is a modern solution for realistic simulation and dynamic scheduling that complements SimPlan AG’s software portfolio. What makes Simio unique is that it combines classic discrete event simulation with real-time production planning in one integrated platform.

This enables companies to make more precise decisions based on realistic data and flexible scenarios.

Your advantages with Simio

- Intuitive drag & drop modelling – no programming knowledge required

- 3D visualisation included – display complex processes without additional effort

- ..

How can we plan the use of resources (personnel, machines, space, etc.) so that we can respond flexibly to fluctuations in demand?

Today, planning means more than fixed capacities and stable demand. Many production managers are faced with the task of having to reschedule resources at short notice while maintaining the same delivery commitments.

How can you plan reliably in this challenging environment?

With the help of simulation, you can check how different shift models, personnel deployment strategies or machine availability affect throughput and adherence to delivery dates – before you implement any measures.

This allows you to identify where buffers make sense, which combinations are truly resilient and how far your processes can be stretched without becoming unstable. Simulation not only reveals bottlenecks, it also helps you develop targeted options.

If your resources are scarce but demands are increasing, we will be happy to show you how you can gain more leeway – with data-based models instead of time-consuming test phases.

Digital twins – efficiency drivers for production and logistics

Digital twins are more than just digital representations of real systems. In Industry 4.0, they play a central role in optimising complex processes – and open up new opportunities for everyone involved in planning, control and continuous improvement.

What makes digital twins so relevant?

1. Holistic view of processes

Digital twins combine data from machines, IT systems and planning tools into a dynamic model. This allows dependencies to be identified, bottlenecks to be simulated and potential for improvement to be uncovered – even before changes are implemented in the real world.