New PacSi and SimQueue functions for packaging and production plants

The portfolio of simulation expert SimPlan ranges from the creation of ‘digital twins’ of production and logistics processes to virtual commissioning and process simulation. At this year’s Fachpack in Nuremberg (23 to 25 September), SimPlan will be presenting a wide range of simulation and software applications that can be used to configure manufacturing and packaging plants, right through to logistics, and to calculate key performance indicators.

Founded in 1992, SimPlan AG is now a leader in the simulation of operational processes. The company’s extensive portfolio includes the PacSi simulation system, which was developed specifically for this industry and its typical processes. PacSi is an in-house development by SimPlan AG that is now used internationally by machine builders and plant operators of processing and packaging plants. Several newly developed PacSi functionalities will be presented at the upcoming Fachpack trade fair. These include a newly developed model generator (SimPacSi) for creating simulation models for PacSi and, as a result, the option of using PacSi as ‘simulation as a service’ (simulation in the cloud). Simulation models can be created in an app-based model generator or via a web front end and then sent to PacSi running in the cloud for simulation. Once the simulation is complete, the results are sent back to the app or web front end and presented. Depending on the licence model, PacSi can be operated in-house (on the company’s own network) or using external infrastructure. As ‘simulation as a service’ is a relatively new simulation option on the market, especially in the field of processing and packaging plants, we are eager to receive feedback from our customers and interested parties at Fachpack and would like to discuss this with them.

Another highlight is the ability to simulate the energy and media consumption of a plant based on the actual operating conditions of the individual machines and interlinking systems with PacSi. Recently presented as a prototype in research projects, this functionality is now included in the standard PacSi licence and has received a lot of positive customer feedback.

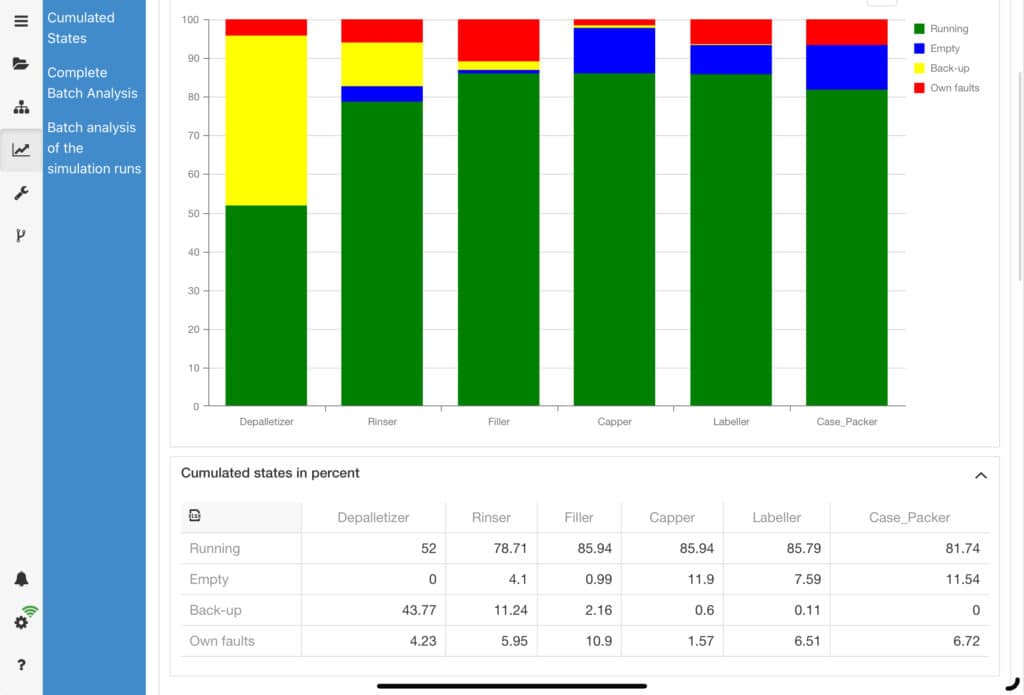

A brand new feature is the option of simple and quick availability calculation, including automated storage optimisation of manufacturing and packaging systems, among other things, for immediate comparison of structure and design variants in the early planning phase.

To this end, SimPlan is presenting the new ‘SimQueue’ app at Fachpack, which is already available for download from the Apple App Store. SimQueue allows production facilities to be optimised quickly and easily during the planning phase. For example, SimQueue can be used to evaluate and optimise the distribution of buffer spaces in the early planning stage.

This supports planners in designing buffer capacities and helps to identify bottlenecks at an early stage.

In collaboration with Hanover University of Applied Sciences and Arts, the calculation functions with extended options, such as an additional OEE calculation, will be incorporated into the further development of PacSi. The initial results of these developments and a preview of many other new PacSi functions, such as the processing of an individual production plan or the future new GUI design of PacSi with many other new functions, can be viewed at FachPack.

Calculations of plant availability and throughput, right through to complete simulation, enable significantly greater decision-making certainty. This is indispensable for the planning, development and optimal operation of highly dynamic processing (manufacturing and packaging) in the food industry, pharmaceuticals and similar sectors (including cosmetics, adhesives and detergents).

The optimal use of resources (minimised consumption and use of valuable raw materials, energy, media and personnel) is an absolute priority for both plant suppliers and plant operators.

The early and reliable performance commitments required for successful business can no longer be met solely on the basis of traditional experience due to the stochastic parameter fluctuations of natural raw materials (products and packaging materials), stricter environmental criteria and the unabated trend towards ever smaller production batches.

This is precisely where simulation methodology comes into play. It is a scientifically recognised and practically proven means of determining performance indicators and optimising interlinked systems. It can be used to determine the necessary plant structures, machine capacities and buffer sizes, as well as energy and personnel requirements and set-up and cleaning scenarios, without any risk.

With SimQueue and the advanced functionalities of PacSi, SimPlan can further significantly lower the entry barrier for simulation. This means that planners, service staff, and sales and purchasing staff can now easily configure a packaging plant without any special expert knowledge of simulation methodology and calculate the output, availability, and efficiency for different variants in advance in a matter of minutes, even without the use of a simulation system. The advantages in sales and distribution processes (trade fairs, customer meetings, etc.) as well as in the early project phases of plant planning are obvious.

The plants created and configured in the calculation environment can, of course, be simulated and optimised in more detail in later project phases using PacSi or Plant Simulation, among other tools.