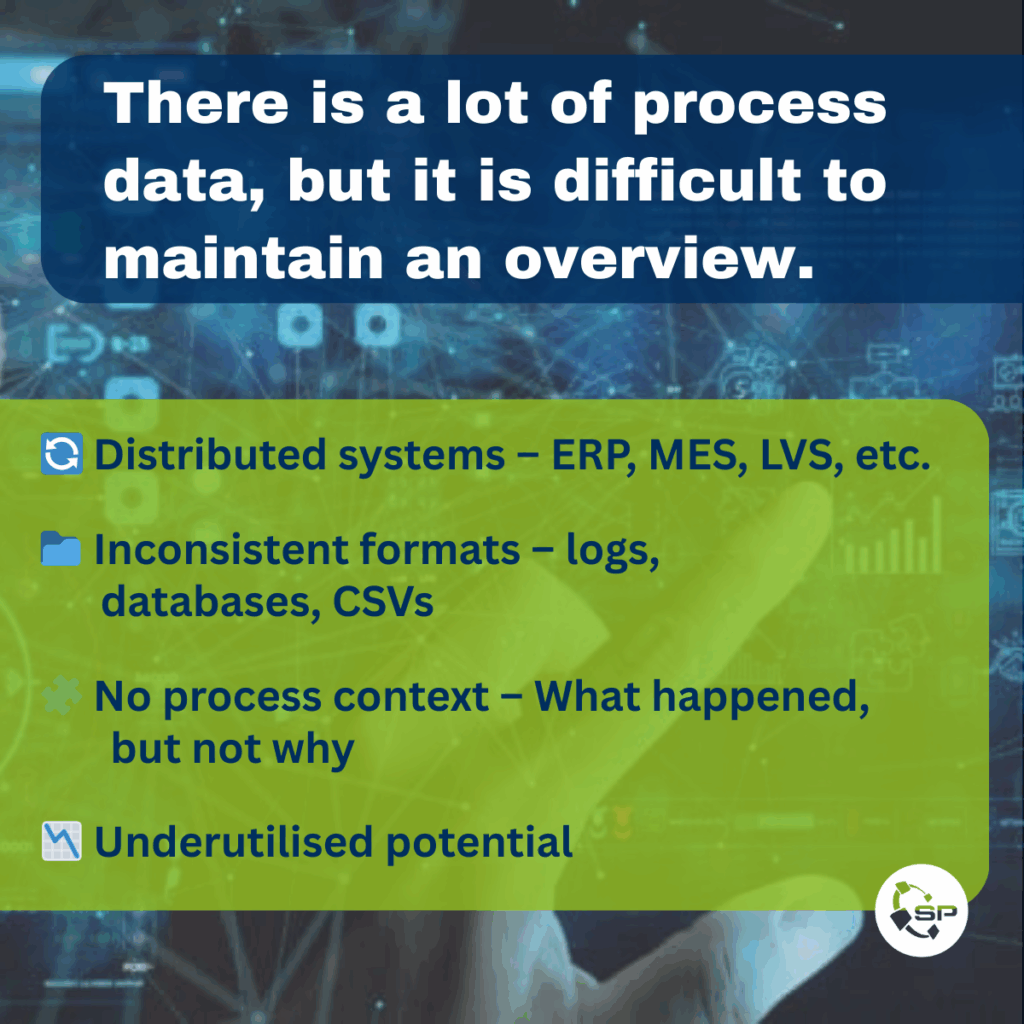

Are you already actively using your process data for optimisation – or is it lying unused in your systems?

Every day, enormous amounts of data are generated in ERP, MES and warehouse management systems. But often this data remains unused because:

- it is stored in different systems and formats

- there is no direct link to processes or causes

- it only shows what happened – not why

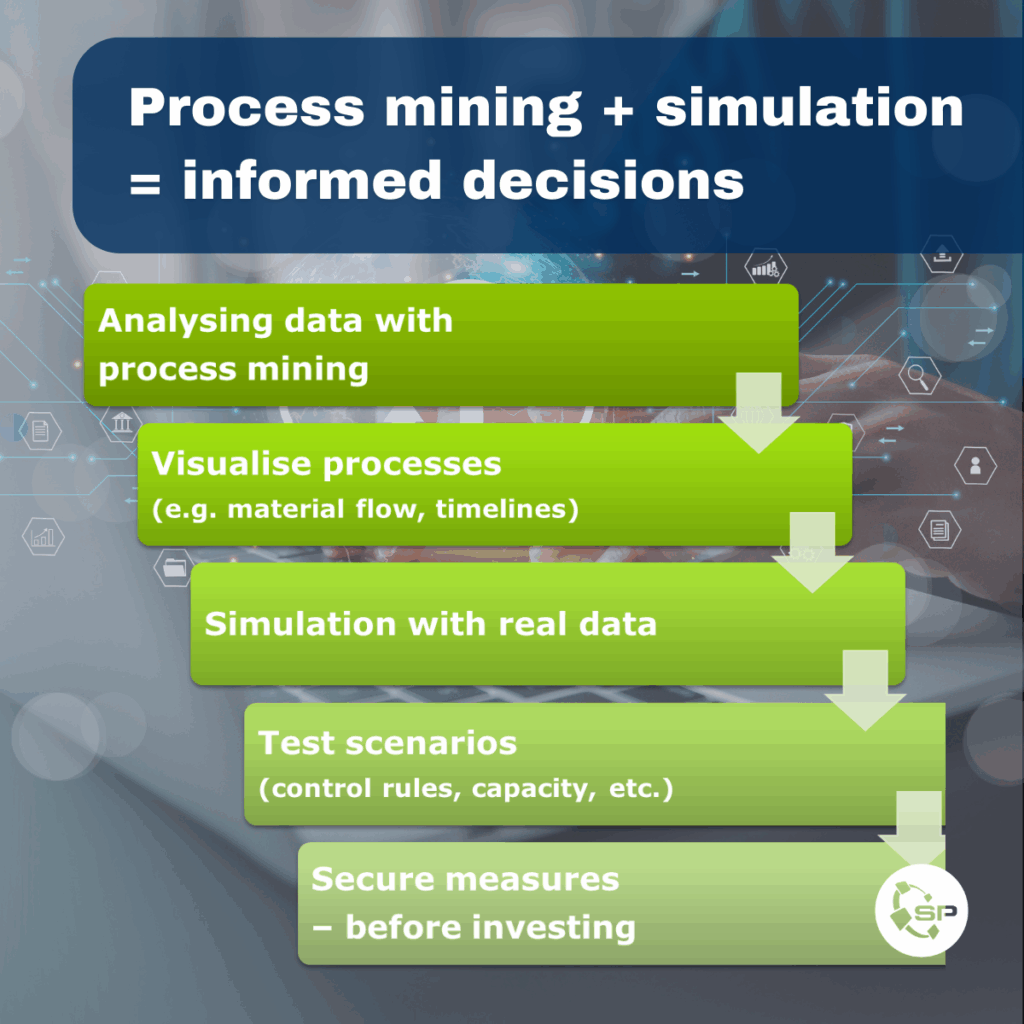

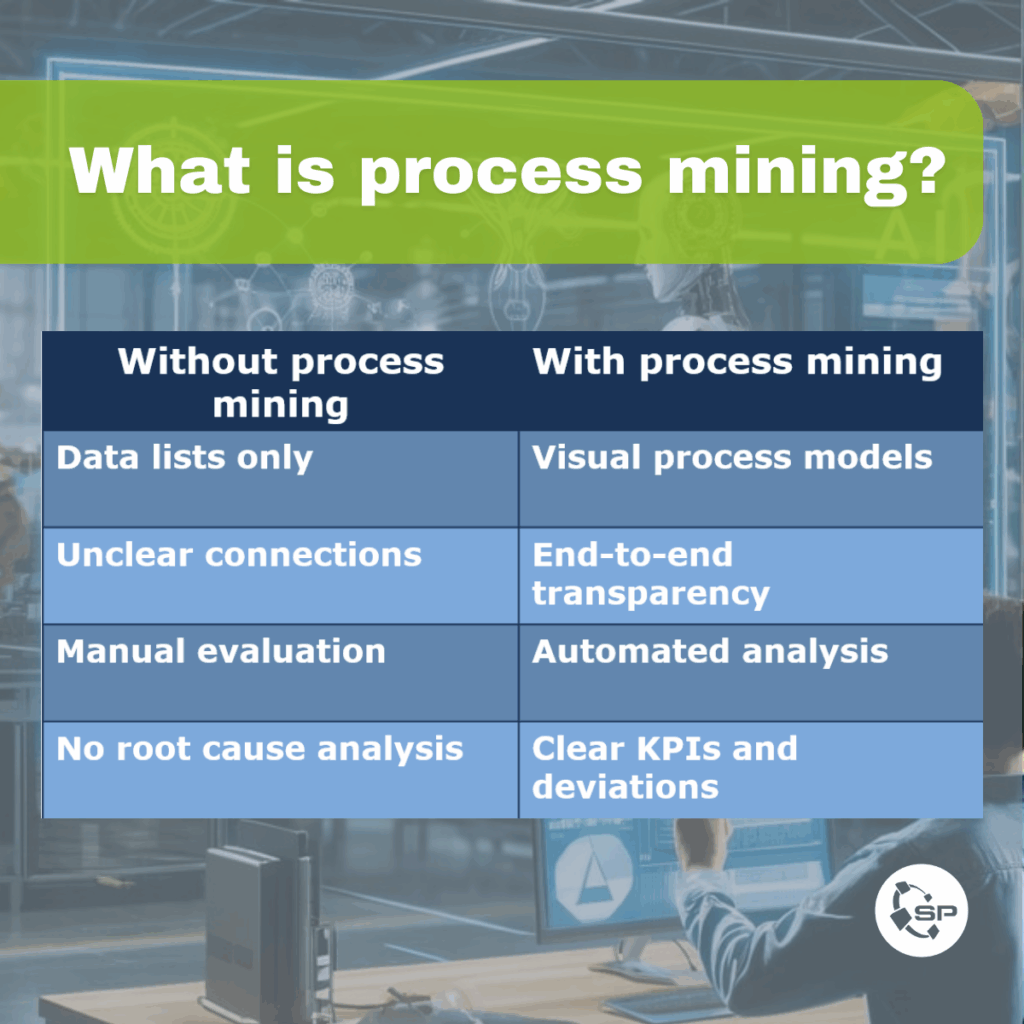

This is exactly where process mining comes in:

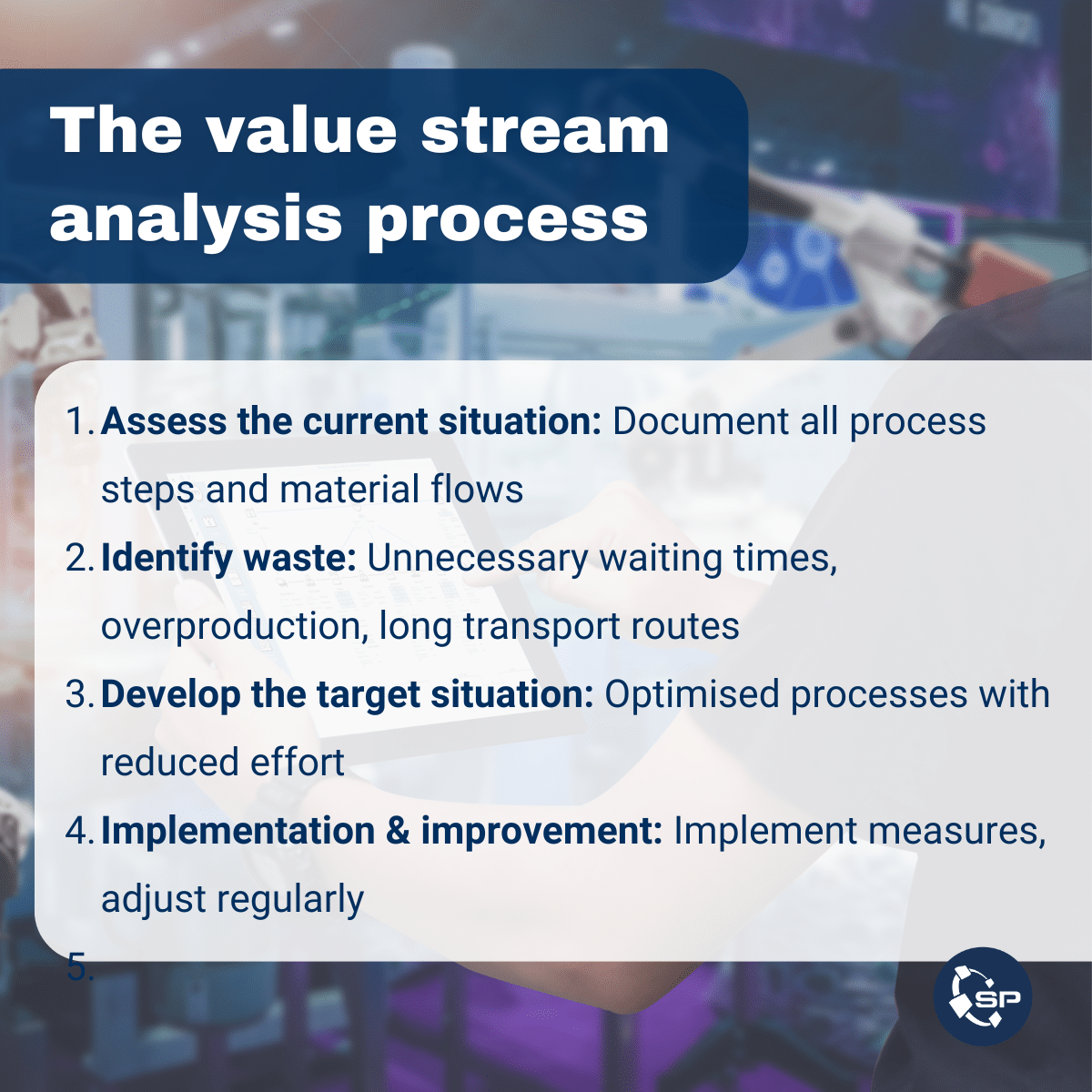

Through the structured evaluation of real process data, workflows can be visualised, bottlenecks identified and potential for improvement derived – in a data-based and objective manner.

SimPlan combines process mining with simulation. The result is more than just visualisation – it is a tool for informed decision-making:

- Automatically generate process maps and material flows

- Identify causes of delays or deviations

- Simulate optimisation measures in advance – on the digital twin

- e.g. with SimPath for automated logistics systems

For more information feel free to contact us.