Research project VaStNet – Optimization of value streams with neural networks

Motivation

In order to design production processes and supply chains efficiently, planners rely on value stream modeling: production processes are often mapped digitally as graphs with production, transport and storage steps. The simulation of these value streams makes it possible to evaluate efficiency, check alternatives, identify bottlenecks and plan resources. Value streams can comprise hundreds of nodes with data such as products produced and transit times. The creation of a value stream is prone to errors and has so far mostly been the preserve of specialists.

Objective and procedure

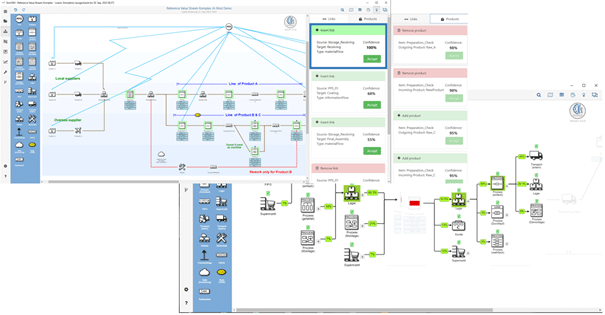

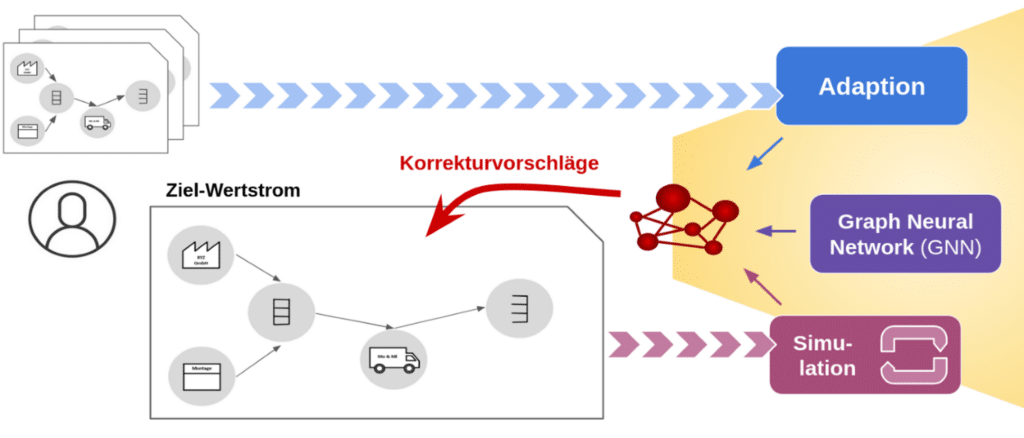

This is where the VaStNet project comes in: The aim is to support users in modeling correct value streams with the help of AI. Learning processes are to act as digital assistants: VaStNet identifies errors in the value stream and makes suggestions for corrections in order to create a simulation-capable and correct value stream. The machine learning problem is formulated in a similar way to language modeling in text AIs: Edges, nodes or attributes are masked out and the model is trained to predict the masked element based on the context.

Innovation and prospects

VaStNet builds on the successful preliminary work of the project partners SimPlan and RheinMain University of Applied Sciences, which used AI methods for the interactive repair of value streams for the first time worldwide. This work is being expanded on three levels:

- Adaptation level: the AI becomes adaptable to specific value streams of a customer.

- Model level: A deep learning model is used.

- Simulation level: The model takes into account the simulation results of the value stream for its recommendations.

The VaStNet assistant is intended to make value stream simulation more accessible and open it up to a broader customer base. In times of skills shortages, supply bottlenecks and fluctuating raw material prices, VaStNet contributes to making production and supply chains more flexible in order to make industrial processes more competitive and sustainable.

Project partner

The research project is funded by the Federal Ministry of Education and Research.

The funding started in April 2024 and will last 2 years.