Planning and optimisation in production

Production processes grow ever more complex and dynamic with the increasing process integration that starts in production itself and reaches all the way to the customer. This leads to new and reocurring tasks in the planning and optimisation of resources and processes. At this juncture, static optimization methods and calculations based on average values start to fail.

The solution is to use dynamic simulation, which is able to depict the complexity and dynamism of production realistically. Simulation brings an unprecedented level of transparency to your production processes, because a simulation model shows cause-and-effect relationships very clearly.

This way, bottlenecks can be analysed quickly and efficiently, and optimization measures can be derived, which then can be tested in the simulation model completely without risk. This safeguards your investment in machines and resources and is more effective than classical investment budgeting that is only aimed at local optimization.

Dynamism and complexity

The use of simulation in production can range from mapping single for the dimensioning of production resources and buffer sizes to the modeling of entire production plants. This also includes simulating intralogistics systems to determine the optimal size of logistics areas and the ideal means of transportation within the production system.

By analysing the entire production process, simulation takes both complexity and dynamism into consideration. Dynamism is caused for example by machine malfunctions, variability of cycle times in manual processes or by resource bottlenecks.

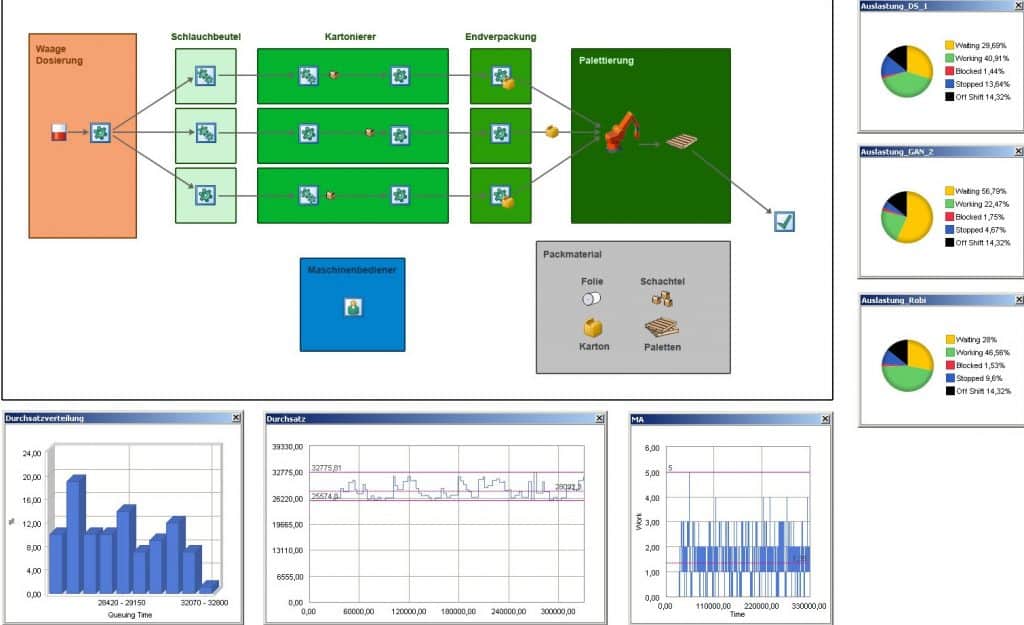

Model of a production line

Results of the simulation

- Visualization of processes

- Capacity analysis for evalution of bottlenecks

- Total throughput of plants (incl. malfunctions, reworking rejections, etc.)

- Real total availability of plants

- Goods in buffers and in stock

- Plant utilization (machines, buffers, materials handling, employees)

- Staff requirements for multi-machine-operation

Aims and benefits

- Improvement and reduction of facility planning times

- Increase of process quality, as bottlenecks are identified already in the planning Phase and can be eliminated with suitable measures

- Optimisation of plant components under realistic conditions

- Optimisation of buffer design to decouple plants and increase throughput and total availability

- Riskless analysis of improvement strategies