From the current state to lean production

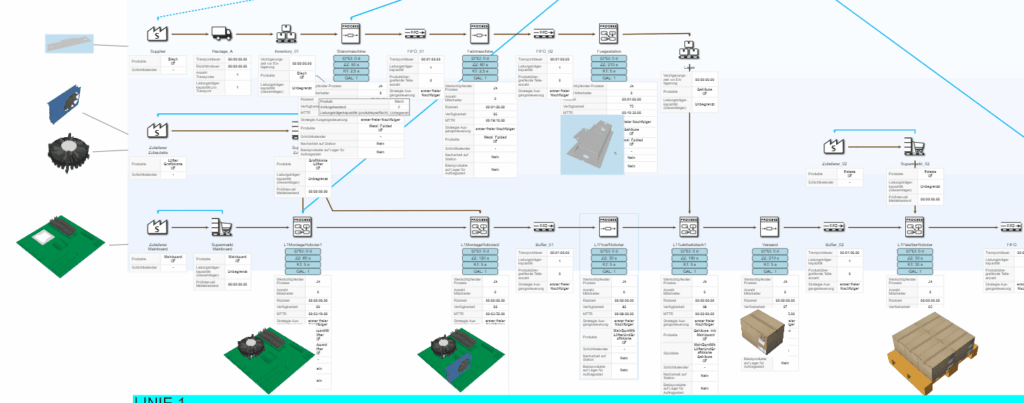

In production and logistics, continuous process optimization is crucial for efficiency and competitiveness. Value stream mapping is a key tool in lean management: it makes material and information flows transparent, separates value-adding from non-value-adding activities, and specifically identifies waste.

Optimization begins with a detailed analysis of the current state. The goal is to identify bottlenecks, unnecessary waiting times, and inefficient processes—the basis for lean, stable, and sustainable process design.

Digital instead of paper – SimVSM as a lean tool

In many companies, value stream analysis is still carried out on paper and then digitized manually – a time-consuming and error-prone process. With SimVSM , this detour is eliminated:

- All relevant parameters (production figures, material and information flows) are recorded on a tablet.

- The process design is carried out directly on the production line.

- Results are immediately available digitally and can be further processed without media discontinuity.

Advantages of digital value stream analysis with SimVSM:

- Efficient, mobile data collection without paper

- Automatic digitization and analysis in real time

- Improved transparency across the entire process

- Rapid identification of lean potential

Simulation as the key to lean processes

Traditional value stream analysis provides valuable insights, but remains static. Dynamic interactions such as setup times, varying production volumes, fluctuating demand, or buffer sizes cannot be represented in this way.

This is where simulation comes in:

- SimVSM not only documents value streams, but also simulates them.

- A web service transfers the model to a simulation server, which calculates key figures such as throughput, bottlenecks, or utilization in seconds.

- This allows scenarios to be compared and improvements to be verified on the basis of data – a decisive step toward sustainable lean optimization.

Adjustments in seconds

SimVSM is platform-independent and can be used on almost any industrial tablet. Thanks to digital modeling, changes can be made quickly and flexibly:

- Drag & drop for quick adjustments and visualizations

- Optimization potential immediately visible

- Iterations in minutes instead of days – without time-consuming post-processing

With this combination of value stream analysis, lean methodology, and simulation, SimVSM offers a practical solution for companies that want to sustainably improve their production and logistics processes – making them leaner, more efficient, and more resilient.

For more information, visit our SimVSM product website.