Planning and optimization in production

The complexity in production and the dynamics are increasing more and more due to a close interlocking of processes from production to customers. This leads to ever new and recurring tasks in the planning and optimization of production resources and processes. Here, static considerations and calculations with average values reach their limits.

These limits can be overcome with the help of a dynamic simulation, which realistically depicts the complexity and dynamics. The simulation enables an otherwise impossible transparency of your production processes in advance, because the cause-effect relationships are clearly shown in a simulation model.

In this way, bottlenecks can be analyzed very quickly and efficiently and optimization measures can be derived, which can then be examined in a simulation model without any risk. This safeguards your investments in machines and means of production and differs from classical investment calculation, which is designed for local optimization.

In addition, the simulation models can be linked to existing production information systems in such a way that a digital twin of the existing production is created. The Digital Twin makes it possible to safely test operational decisions on the digital model before they are transferred to the real system. The Digital Twin is thus an ideal decision support tool.

Dynamics and complexity

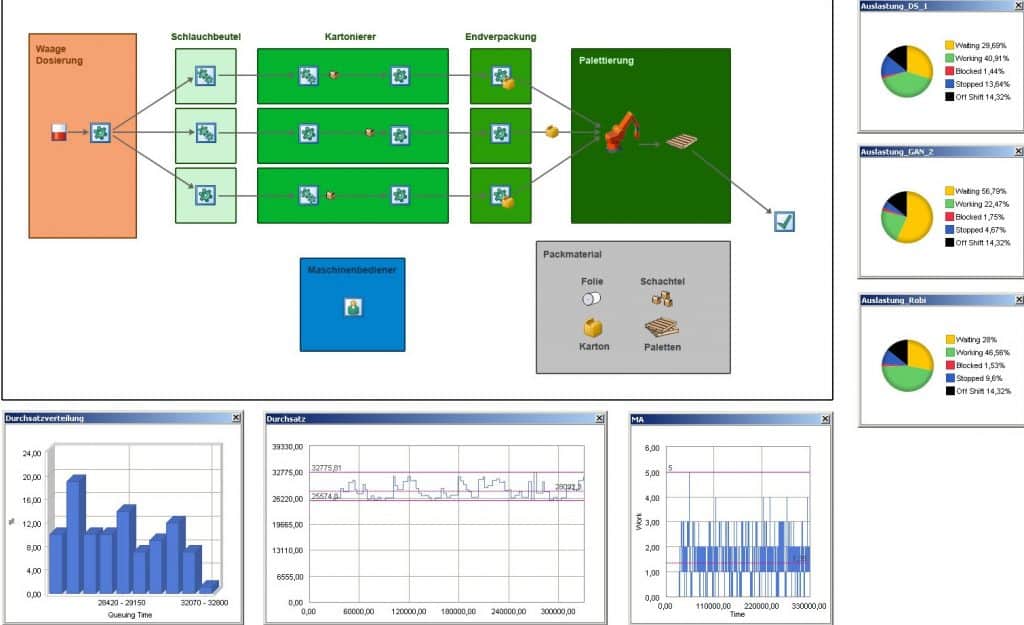

The use of simulation in the area of production includes the mapping of individual lines from the layout of production resources and buffer sizes to the mapping of entire production halls. This also includes intralogistics systems for the coordination of logistics areas and the optimization of means of transport.

The simulation considers the dynamics as well as the complexity resulting from the analysis of an entire production process. Dynamics are caused, for example, by machine malfunctions, cycle time fluctuations due to manual processes or access to a bottleneck resource.

Model of an interlinked production plant

Simulation results

- Visualization of the processes

- Capacity analysis to identify bottlenecks

- Total throughput of a plant (incl. malfunctions, rework, scrap, etc.)

- Real overall availability of the plants

- Stocks in buffers and warehouses

- Utilization over time (machines, buffers, conveyors, employees)

- Personnel requirements for multi-machine operation

- Cost analysis

Goals and benefits

- Improvement and shortening of the planning of plants

- Increase of process quality, since bottlenecks can already be identified in the planning stage and eliminated by appropriate measures

- Optimization of plant components under realistic conditions

- Optimization of buffer design to decouple plants and increase throughput and overall availability

- Risk-free investigation of improvement measures

- Process model for the digital twin