Digital value stream mapping and analysis as the key to informed decisions

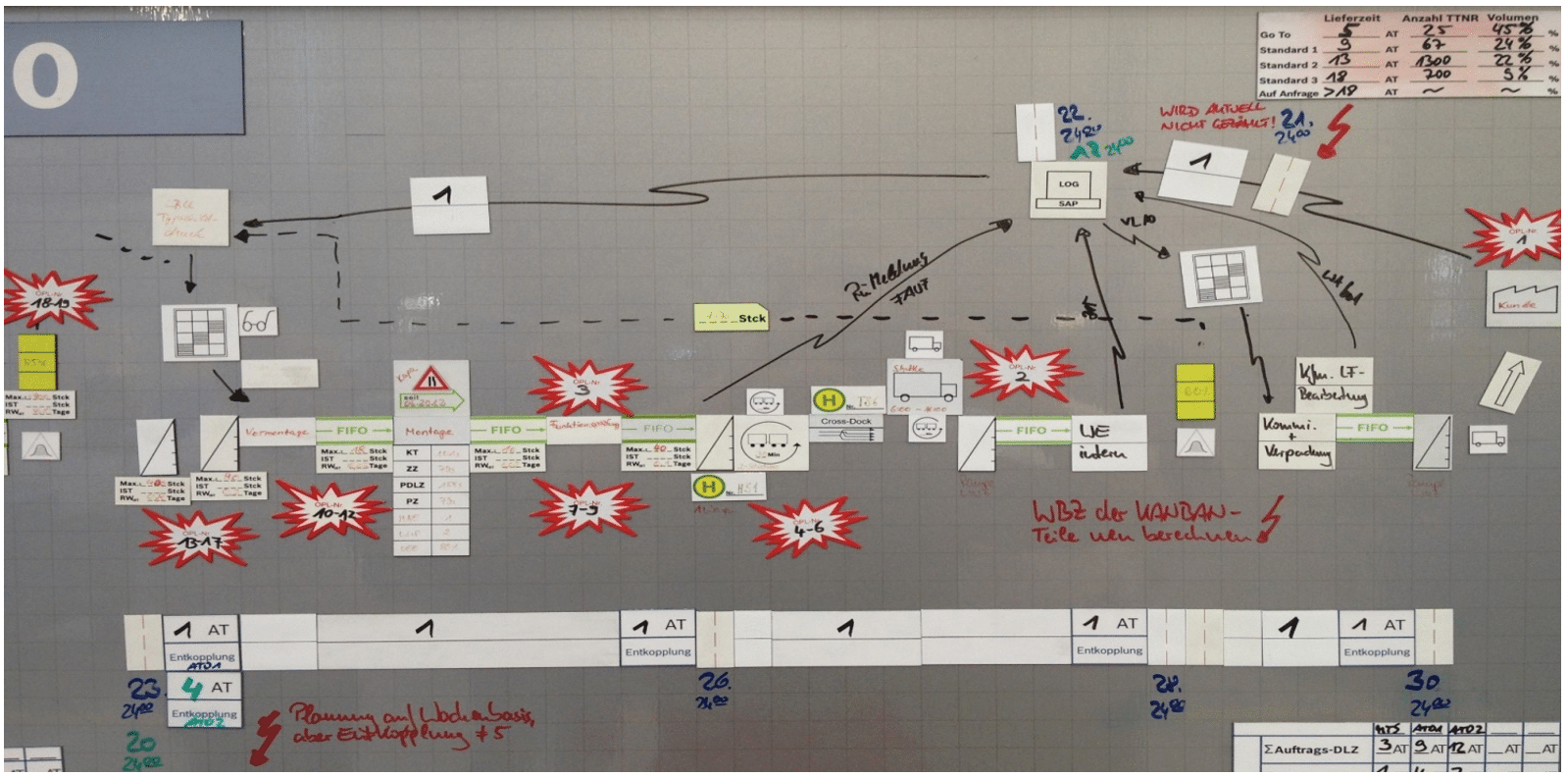

In many companies, large value stream maps are still displayed on paper (brown paper) or whiteboards. With colourful notes, arrows, time specifications and a lot of teamwork, workshops often produce important analyses of the current process landscape. But what happens afterwards? These maps often disappear into photo folders or archives and quickly lose their value.

In an increasingly dynamic production world, this is no longer sufficient. Supply chains are changing, product variety is growing and customer expectations are rising. Those who only analyse their value streams occasionally often react too late instead of making informed, forward-looking decisions.

Value stream mapping remains relevant, but the methods are changing

The value stream mapping (VSM) method has proven itself in lean management over many years. It helps to visualise complex processes and identify waste, for example through waiting times, duplication of effort, oversized buffers or missing information. However, the traditional paper-based approach has clear limitations:

- There is no way to compare variants or run through scenarios

- Data such as throughput times, utilisation rates or inventories must be calculated manually

- Changes in the process are difficult to track

- Results are difficult to share across teams or reuse

What makes digital value stream analysis better

Digital tools such as SimVSM enable a new form of value stream analysis: model-based, networked and simulation-capable. Value streams are created directly on a tablet or desktop, key figures are calculated automatically and variants can be easily duplicated. This not only saves time, but above all creates transparency and comparability.

Digital models are available at any time and can be continuously developed. Changes in the shift model, new products or delivery delays can be incorporated directly into the model without having to start from scratch each time.

From observation to data-based decision-making

A key advantage of digital value stream analysis is its link to real data. Information from shop floor systems, MES or ERP can be integrated and systematically evaluated. This turns the classic Gemba Walk into a real data walk with reliable decision-making bases for continuous improvement processes.

Even complex issues such as variant diversity or capacity limits can be realistically mapped and simulated.

SimVSM in practice: modelling, analysing, simulating – now also with AI

SimVSM is a tool that has been specially developed for these requirements. The app makes it possible to model value streams simply by drag & drop. Key figures such as cycle time, throughput or inventory are calculated automatically. In the Pro version, scenarios can also be simulated, for example to evaluate measures, identify bottlenecks or analyse alternative processes.

New is the integrated AI feature (available from January 2026). This allows analogue value stream maps from the workshop to be transferred directly to the app. A photo is all it takes to create a digital model. This saves additional transfer work, reduces errors and speeds up the transition to digital analysis.

This has two advantages: firstly, risks in real production can be avoided. Secondly, decisions are made in a more informed, faster and more transparent manner and are also documented in a way that is comprehensible to stakeholders.

Now is the right time to make the switch

Many processes today change faster than an analogue value stream map can be updated. If you want to use value stream analysis not just selectively, but continuously and data-based, there is no way around digital solutions.

Whether for lean projects, production optimisation or as part of a digitalisation strategy, digital value stream models create a link between operational process knowledge and strategic control, transforming a workshop tool into a permanently usable analysis instrument.