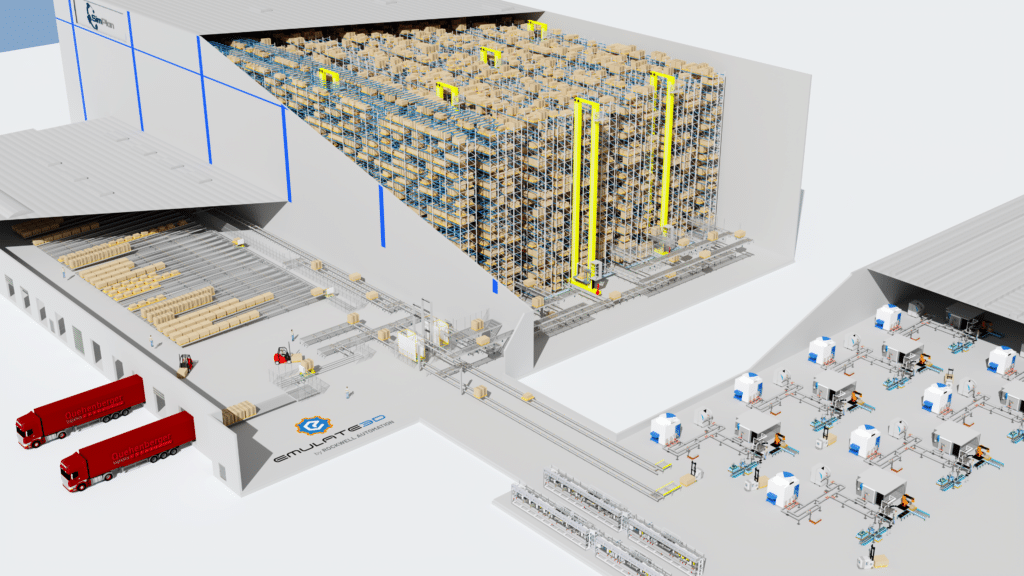

Emulate3D – Digital twins for production and logistics

Introduction to the tool

Emulate3D is a powerful software for simulating and virtually commissioning automation systems, which supports mechanical and plant engineering projects throughout the entire project period. It enables realistic 3D models that integrate control logic, robotics and material flow.

Simulation enables companies to test processes at an early stage, reduce errors, shorten throughput times and lower investment risks. Virtual commissioning makes it possible to put PLC controls and even higher-level control systems into operation at an early stage and independently of the actual mechatronics, significantly reducing costly on-site deployment and commissioning risks. Emulate3D can be used across all industries, both in mechanical and plant engineering.

Areas of application and typical uses

- 3D layout planning

- Immersive engineering using virtual reality and augmented reality

- Simulation of production and logistics systems

- Performance determination

- Dimensioning of plant components

- Bottleneck analyses

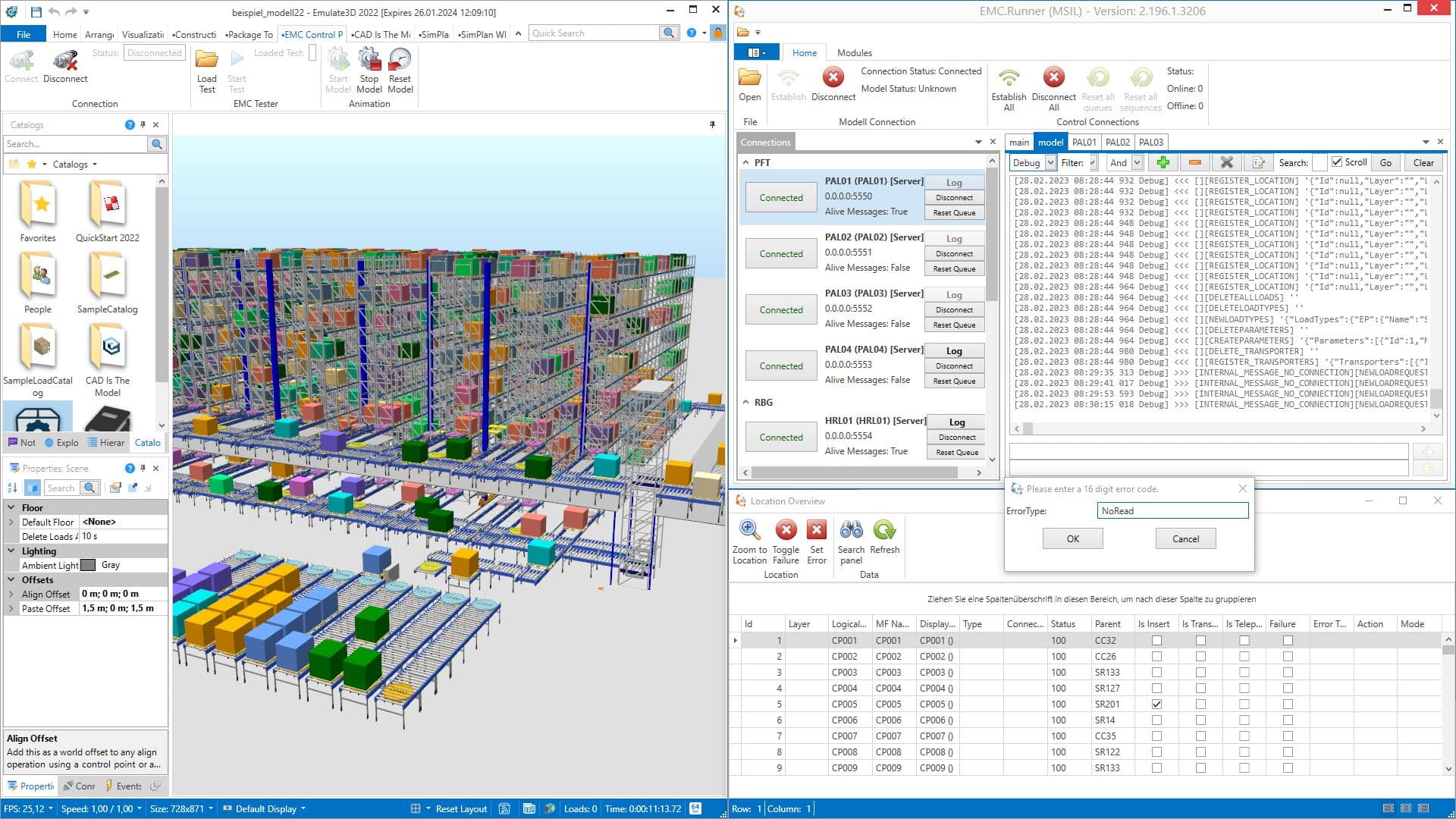

- Virtual commissioning

- Testing PLC programmes for errors

- Testing material flow computers for errors

- Training environments for personnel

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationKey features and strengths

Since its inception, the software has impressed with its high level of innovation in further development. Trends and new technologies are identified early on and put to use.

- Wide range of standard libraries and functions available

- Can be individually expanded with smart modules and functions

- Highly detailed 3D models, including physics-based simulation

- Open approach, e.g. numerous 3D CAD interfaces

- Interfaces to a wide range of automation platforms (Siemens, Rockwell, etc.)

- Support for a wide range of mechatronic solutions such as machines, robots, transport systems, storage systems, etc.

Structure and available modules

Digital twins can be created in Emulate3D either on the basis of parameterisable standard components or on the basis of 3D CAD data. Emulate3D provides thousands of standard modules in so-called catalogues for this purpose, as well as the ‘CAD-is-the-model’ module for the kinematisation of CAD data. The ‘Testrunner’ and “Analysis” modules are available for simulations to run and evaluate runs. The ‘IO Browser’ module is used to connect controllers during virtual commissioning.

Versions and licence models

The different areas of application for Emulate3D are supported by various editions of the software that build on each other. These are

- Emulate3D Layout (layout planning)

- Emulate3D Demonstrator (animation, visualisation)

- Emulate3D Simulator (process simulation)

- E3D Ultimate (virtual commissioning)

All licences are network licences, which are offered as both subscription and purchase (perpetual) licences. In addition to commercial licences, educational licences are also available.

Integration and interfaces

Emulate3D has a large number of native CAD interfaces, including AutoCAD, Inventor, Creo Parametric, SketchUp, SolidWorks and NX. Imports are also possible via STP or VRML. Structures and layers are retained during import. In addition, the data can be simplified automatically.

Numerous interfaces for hardware-in-the-loop and software-in-the-loop are available for connecting PLC controllers. These include, for example, connections to Siemens, Rockwell, Beckhoff, B&R and Omron. Communication with higher-level systems is possible via TCP/IP, UDP, MQTT or OPC UA, for example.

Frequently asked questions (FAQ)

Can Emulate3D also be used to model large systems?

Yes, Emulate3D can also be used to build large models. This is particularly true when using the internal modules, as these are very powerful. However, thanks to the powerful ‘Unreal’ rendering engine, models with large amounts of 3D CAD data also work.

Is virtual commissioning cost-effective?

It is often difficult to quantify the specific savings achieved through the use of virtual commissioning, as there are simply too many influencing parameters in projects. However, numerous statements from users of virtual commissioning suggest that the time invested and thus the costs are ultimately worthwhile. In addition, many tenders now stipulate virtual commissioning from the outset.

How accurate are Emulate3D’s physics simulations?

Emulate3D offers a choice of four different physics engines, each with its own advantages. Overall, they allow the physical behaviour of bodies to be simulated quite accurately. Numerical simulation can, of course, produce even more accurate results, but only at the cost of significantly longer computing times. This makes it unsuitable for process simulations and VIBN.

Manufacturer and source

Since Emulate3D was acquired by Rockwell Automation in 2019, this manufacturer has been responsible for its further development. With the first release, SimPlan took over the distribution partnership for the European region. In addition to the software, SimPlan also offers related services, training and first-level support.