Are you planning new plants, processes or product launches and want to get up and running faster?

In a dynamic market environment, the speed with which new products or plants go into operation often determines economic success. But accelerating the so-called ‘time-to-market’ carries risks: errors in planning, late adjustments or unrecognised bottlenecks can quickly negate the advantage. This is exactly where simulation comes in.

Virtual models of plants, processes and workflows make it possible to test ideas and concepts in a realistic manner before they are implemented. Decisions become more informed, planning errors become visible and optimisations can be implemented at an early stage. The following seven tips show how simulation can help to shorten your time to market – in engineering, production and logistics.

1. Plan simulation early on

In many projects, simulation is only incorporated once the fundamental decisions have already been made. This reduces its usefulness to late-stage control rather than early-stage design.

Our tip: Integrate simulation right at the start of the project. This allows you to compare variants, validate concepts and make realistic assumptions before time and budget are committed.

2. Compare variants digitally instead of testing them in real life

Which layout variant is more efficient? Which material flow avoids bottlenecks? Such questions can be answered better digitally than in a late real-life test.

Our tip: Use the digital twin to run through scenarios and identify the best solution based on data – before building or commissioning.

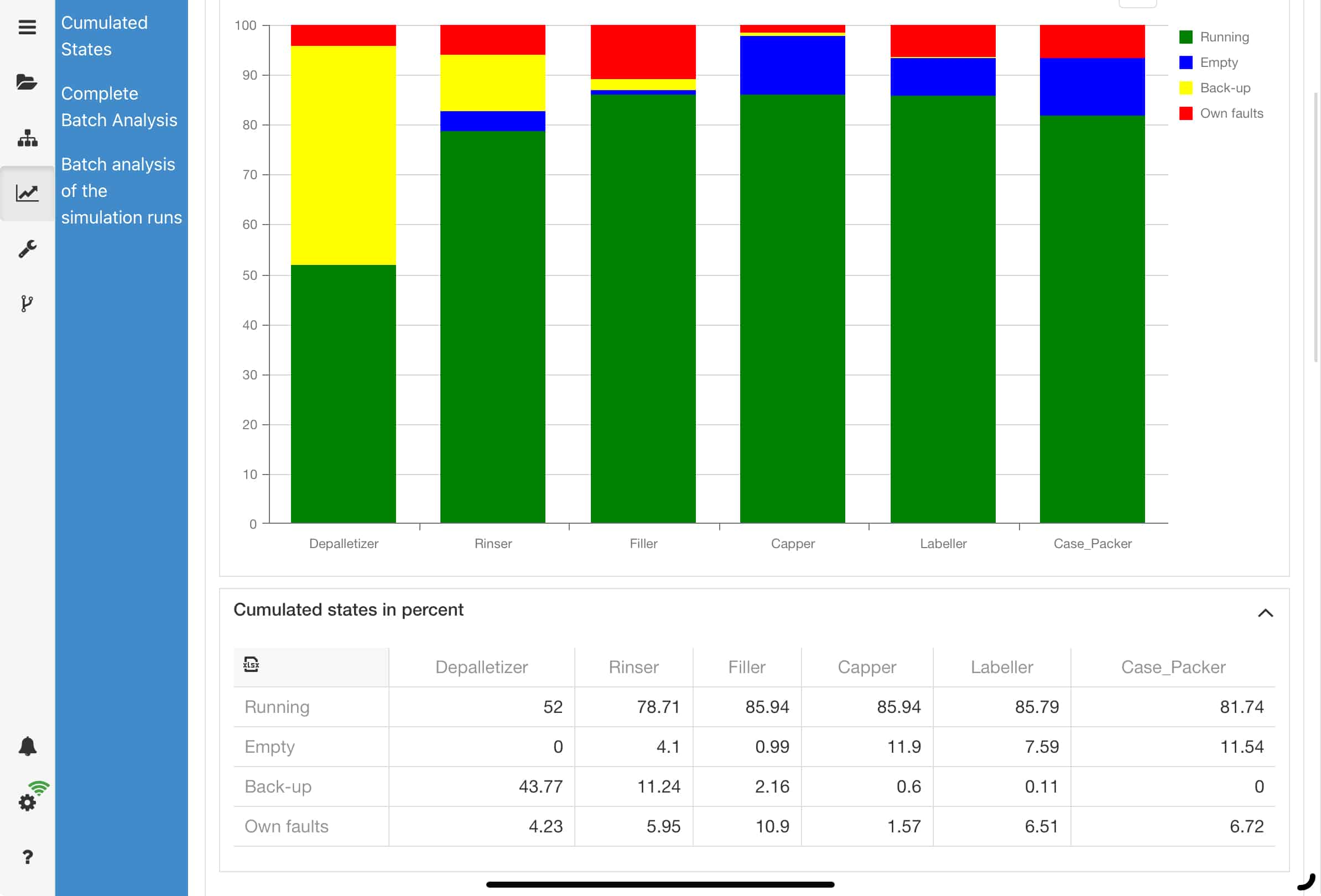

3. Identify and avoid bottlenecks early on

Undetected bottlenecks in material flow, machine utilisation or staff availability often lead to delays in the start of production.

Our tip: A simulation reveals such weak points as early as the planning phase. This gives you time to take targeted countermeasures and avoid costly adjustments late in the project.

4. Prepare for virtual commissioning

Commissioning is often the critical path in the project plan. Every unplanned downtime costs time and money.

Our tip: Test processes, interfaces and control logic virtually before installing real components. Virtual commissioning reduces sources of error and speeds up ramp-up.

5. Plan ramp-up scenarios realistically

The ramp-up of new plants or products rarely runs smoothly. Without preparation, output and availability decline.

Our tip: Simulate different ramp-up scenarios to understand the realistic performance of your processes under start-up conditions and improve them in a targeted manner.

6. Use simulation models multiple times

Building a model for a one-time project purpose wastes potential.

Our tip: Plan your model in a modular and documented way so that it can be reused for future optimisations, training or adjustments. This saves time and increases the sustainability of your investment.

7. Simulate production planning realistically

Paper is patient, but real production is complex. Even well-thought-out plans can falter in practice if restrictions such as staff shortages, set-up times or fluctuating availability are not taken into account.

Our tip: Take specific restrictions in your production into account in the simulation: shift models, set-up cycles, material supply, plant availability or staff shortages. This creates a realistic, reliable picture of your production processes – and you avoid unexpected disruptions at the start.

Simulation is an accelerator with vision

If you want to be faster to market, you need to make decisions earlier and on a more informed basis. Simulation offers decisive advantages here: it creates transparency, reduces risks and makes variants comparable. At the same time, it supports communication between planning, engineering and management through comprehensible, data-based scenarios.

Whether in plant planning, production preparation or series production start-up – simulation not only shortens your time-to-market, but also increases quality and efficiency. The key is to use simulation not as a late control instrument, but as an integral part of your planning.

Contact us

Would you like to learn more about how simulation can be used in your company? Our team is available for a no-obligation consultation or web meeting.