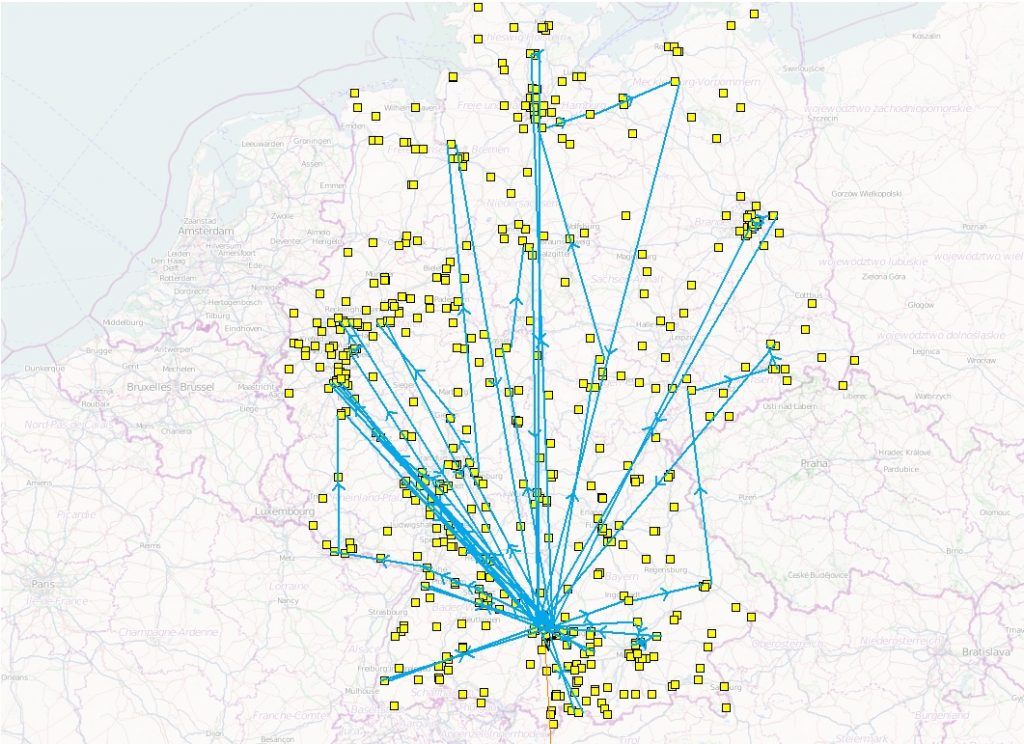

Simulation of a supply chain network

Creating stable and transparent supply chains

Supply chains are among the most complex systems in industry and logistics today. Studies show that up to 80% of the total costs of a supply chain depend on the geographical location of suppliers, production sites, and warehouses, as well as on the flow of materials between them.

In practice, however, supply chains have often evolved over time. In industries such as automotive and mechanical engineering in particular, a large number of suppliers, different order and delivery cycles, global transport networks, and varying end customer requirements lead to highly dynamic relationships.

The optimization of such networks often focuses only on specific aspects, such as reducing transport costs or shortening delivery times. The consequences for other areas of the supply chain usually only become apparent later on – often involving costly adjustments.

To avoid these risks, it is crucial to create transparency across the entire supply network. This is the only way to take all relevant factors into account, reliably assess the impact of measures, and strengthen the resilience of the supply chain in the long term.

Tools and methods

The software applications of the SimChain toolset enable SimPlan to create a digital twin of a supply chain in the computer, with which a well-founded investigation of concrete measures and the evaluation of their effects is possible.

In addition to the analysis of structural bottlenecks, the behavior can also be examined under consideration of dynamic influencing variables (disturbances, fluctuating capacities, flexible retrieval behavior, etc.). Alternatives can be compared and evaluated in detail.

The evaluation of simulation results is very closely oriented to the key figures valid for the supply chain, such as delivery time, delivery reliability, change flexibility and, of course, costs. The structure of a corresponding key figure system in the simulation model can be oriented to the real system or even designed and tested with the help of the simulation.

The SimChain toolset consists of the following software applications:

- anyLogistix, software from AnyLogic Company for the design and simulation of supply chains;

- SimChain library, a self-developed module library based on Plant Simulation for the design and simulation of supply chains.

- Supply Chain Suite (SCS): Your ERP system expanded to include comprehensive supply chain management

- KNIME, an ETL software (ETL: Extraction, Transformation, Loading) for the analysis and transformation of supply chain data into a readable format for optimization or simulation;

- A Python working environment, if complex data analyses and transformations are to be carried out that cannot be represented with the ETL software.

Your benefit

With SimPlan, you benefit from a comprehensive service—without needing any simulation or software expertise yourself:

- Analysis and documentation of your supply chain

- Development of a suitable key performance indicator system

- Creation of a digital twin

- Conducting simulation experiments and business cases

The result: clear recommendations for action that demonstrably increase the cost-effectiveness and resilience of your supply chain. On request, SimPlan can also support you in implementing the measures.