You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationanyLogistix – multi-method simulation tool for supply chain optimisation

Introduction to the tool

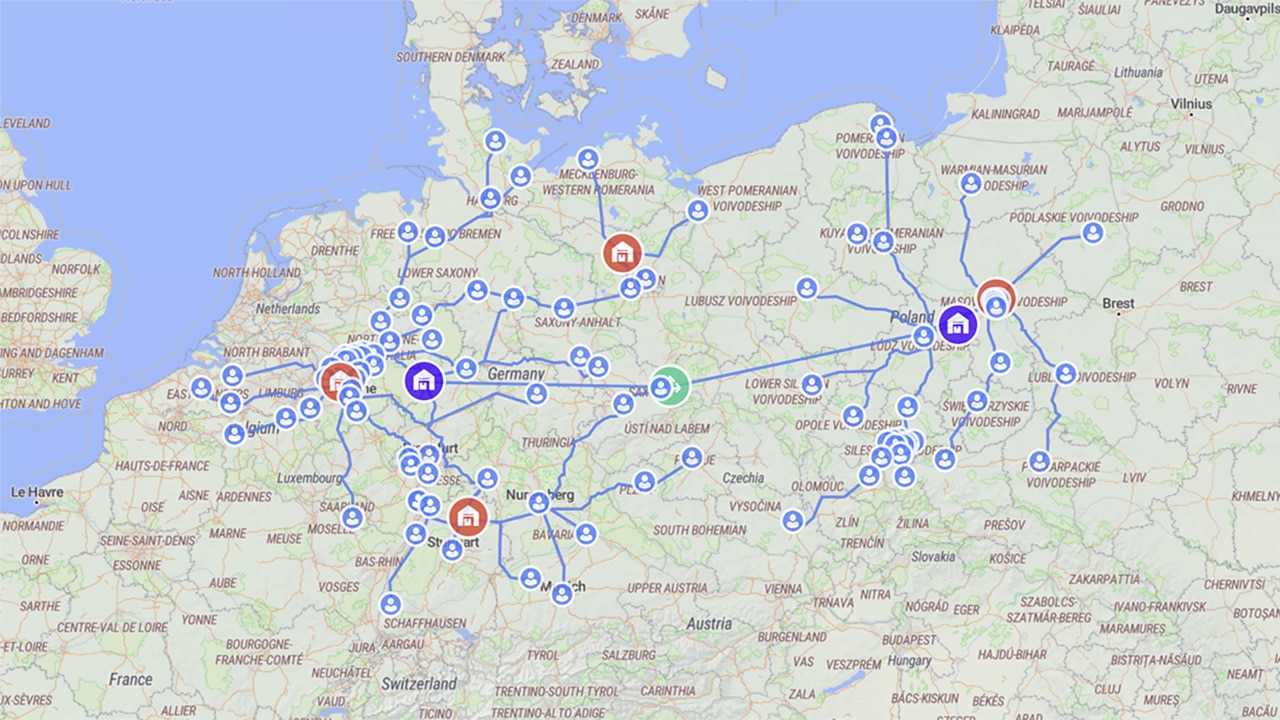

anyLogistix (ALX) is a software tool for analysing, designing and optimising supply chains based on a digital twin. The tool’s unique feature is its combination of analytical network optimisation and dynamic simulation. This allows both strategic decisions – such as location planning or network design – and operational issues relating to inventory, transport, risk and resilience to be examined. anyLogistix is aimed at companies that want to make their supply chain more transparent and make informed decisions. Thanks to its intuitive model structure, the tool is also suitable for beginners who are new to supply chain simulation or digital twins.

Areas of application and typical uses

anyLogistix is used to holistically map, evaluate and improve supply chains. Typical application scenarios include:

- Strategic network design and location planning

- Analysis of transport routes and delivery times

- Evaluation of inventories and safety stocks

- Simulation of demand fluctuations, disruptions and uncertainties

- Evaluation of alternative scenarios (e.g. nearshoring, production relocation, new warehouse locations)

- Risk assessment and resilience enhancement

- Development of a digital twin for continuous supply chain monitoring

Another area in which ALX excels is its ability to not only simulate the network as a whole, but also to model processes within warehouses, factories or distribution centres in greater detail.

Key functions and strengths

anyLogistix combines several functions in a single tool:

Network optimisation

Optimisation methods – with IBM ILOG CPLEX in the background – can be used to calculate optimal network structures. This includes location decisions, transport networks, utilisation and cost comparisons.

Dynamic simulation

The supply chain is mapped as a dynamic system. This allows fluctuations, random factors, capacity bottlenecks and time-dependent effects to be realistically represented.

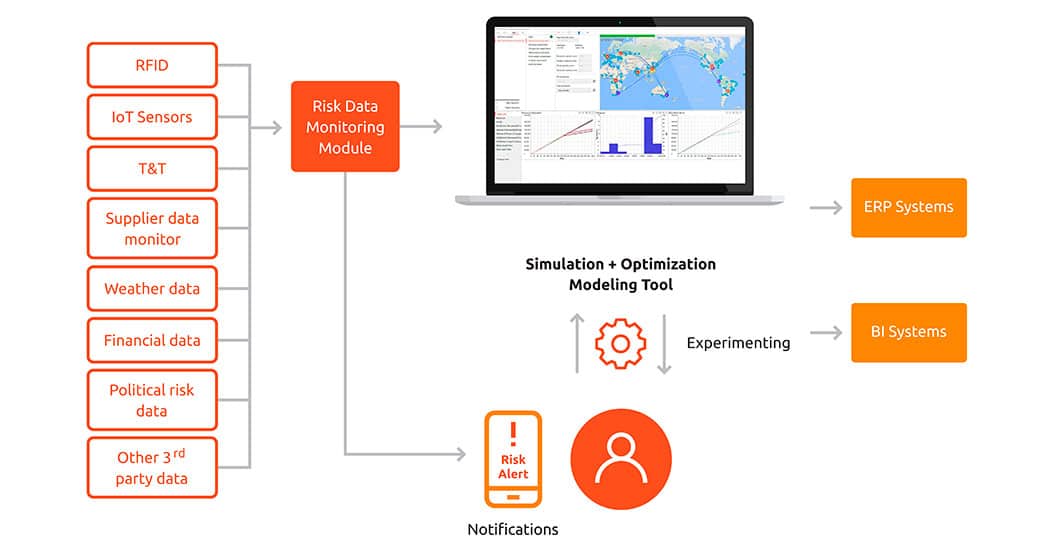

Digital twin of the supply chain

A digital twin enables the analysis of current operating data, the creation of forecasts and the evaluation of changes in ongoing operations.

Risk and uncertainty analysis

ALX can simulate disruptions, demand fluctuations or delivery problems and shows how sensitive the network is to changes.

Simulation within the four walls

In addition to the network level, ALX also supports detailed analysis of warehouse and production processes – right down to conveyor technology, means of transport and individual flow points.

Visualisation and transparency

Map views, interactive diagrams and animations make model behaviour and simulation results comprehensible and facilitate validation.

Functional areas and experiment types

anyLogistix offers various integrated experiment types that support different questions:

- Network Optimisation

- Greenfield Analysis

- Simulation

- Risk Analysis

- Inventory Optimisation

- Transportation Optimisation

- What-if analyses

- Digital twin operation (with data connection)

These experiment types form the methodological core of the tool and enable structured, comparable analyses.

Versions and licence models

anyLogistix is available in several editions, which differ in terms of functionality and scope of application. The most important variants are:

- anyLogistix Personal Learning Edition (PLE) – free version for learning purposes

- anyLogistix Professional – full version for businesses

- Additional extensions such as optimised data integration or advanced analysis functions

Licence models are generally available as annual or multi-year subscriptions.

Integration and interfaces

anyLogic can be connected to existing IT systems to automatically integrate data and continuously update models. Among other things, it supports:

- Excel and CSV data

- ERP and WMS systems (via data export/import or API integration)

- GIS/geodata

- Direct model linking with AnyLogic for advanced simulations

Centralised data storage makes it possible to regularly update models and use them in operational mode.

Frequently asked questions (FAQ)

Is anyLogistix suitable for beginners?

Yes, many areas of the tool are intuitive, and the experiments guide you step by step through typical analyses.

Can I use it to create a digital twin of my supply chain?

Yes. With data connectivity, models can be operated as digital twins.

Do I need programming skills?

Basic knowledge is helpful, but not essential. Many functions are based on graphical modelling.

Can the tool be integrated into existing systems?

Yes, via flexible import/export paths and API options.

Case study: Supply chain optimisation – scalable solutions for the building materials industry

SimPlan supported a large German building materials manufacturer with 24 plants and 6,000 products in optimising its supply chain.

The goal was to develop a scalable and cost-efficient network for the forecasted growth until 2030.

Challenges included deciding between a centralised or decentralised structure, selecting the optimal locations for production and storage, and evaluating the impact on delivery times, transport costs and inventories. SimPlan used the anyLogistix software to analyse and optimise the network.

Manufacturer / Source

The manufacturer of anyLogistix is The AnyLogic Company. SimPlan AG is the official distribution partner in the DACH region.

Further information, downloads and versions can be found directly on the manufacturer’s website: www.anylogistix.com.