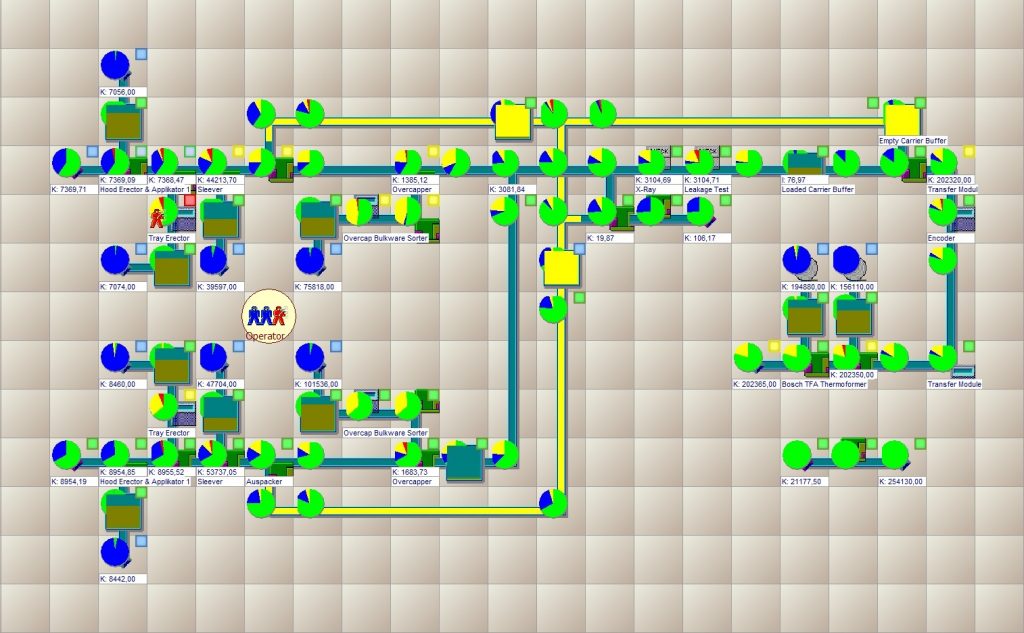

PacSi model of a production line for filling and packaging baby food with a carrier circulating system, including bottleneck analysis

Simulation in packaging industry

Packaging machines are generally highly specialised systems with heavy demands upon speed, performance and process reliability. To meet these challenges, engineers need customised solutions that are tailored individually to each customer and at the same time able to guarantee the expected performance of the system.Dynamic material flow simulation is a proven way to determine key performance indicators and to optimise the interlinked systems that are customary in the packaging industry. It can specify the necessary machine capacities and buffer sizes in advance without any risk.

Simulation of complex systems with PacSi

PacSi is a simulation system especially designed and optimised for the analysis of the highly dynamic and performant systems in the consumer goods and packaging industry. It is used predominantly in the food, pharma, cosmectics and chemical industry, for example to simulate manufacturing systems for food and luxury products, animal food, cosmetics, textiles, paper and plastics as well as pharmaceutical products.

For all system components, PacSi models material flow, time- and quantity-dependent performance as well as the control algorithms. In contrast to many other such systems, PacSi uses a discrete-time approach to simulating these systems and is thereby able to find solutions much quicker, simulating a variety of scenarios within minutes instead of hours.

The simulation models show the efficiency and availability of the single components and the overall system. Influences, for example thermic or rheological, of system components on productivity and availability are taken into account as well.

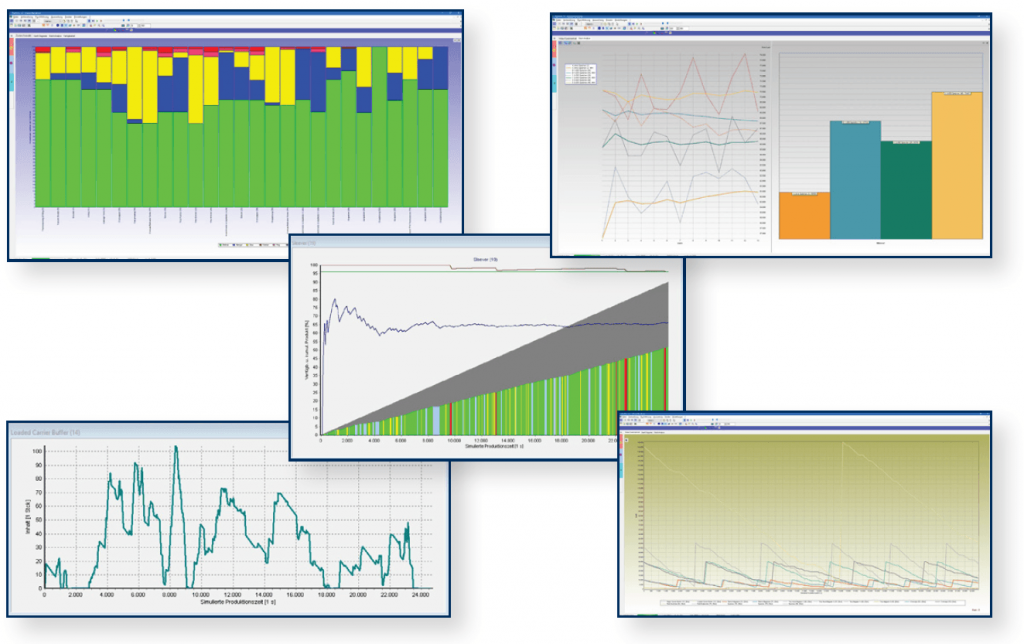

PacSi offers a wide variety of evaluation options

PacSi contains all features necessary for model creation, running simulations and evaluating the results. These features are based on an included standard element library, consisting of verified elements.

PacSi can be used as a decision support tool in any project phase, during planning as well as for process optimisation. The use of the tool requires in-depth process knowledge about the system to be modeled. However, complex mathematical calculations or programming knowledge are not necessary.

The PacSi simulation system was and is developed and serviced by the IKA Dresden. The IKA Dresden uses PacSi to provide simulation services to its customers, but companies may also licence the tool for independent use.

Special features of PacSi

Line structure and efficiency

- Takes into account:

- Machines

- Interconnected elements

- Number of operators

- Manual packing

Detailed operator strategy

- Takes into account:

- Operator position

- Transit times

- Priorities of the activity

- Distinction between:

- Operator activity, and

- Rectification of malfunctions

Production optimisation

- Takes into account:

- Layout variants

- Line performance

- Malfunction behaviour

- Changeover time matrix

- Job size

- Planning scenarios

- Delivery deadline