Innovative technologies for realistic insights and efficient decisions

Immersive technologies such as 3D animation and virtual reality (VR) are becoming increasingly important in the modern planning of production and logistics systems. They enable complex systems to be visualised realistically at an early stage of the project and offer interactive options for analysis and optimisation. SimPlan AG uses these technologies specifically to make projects more efficient, flexible and easier to understand.

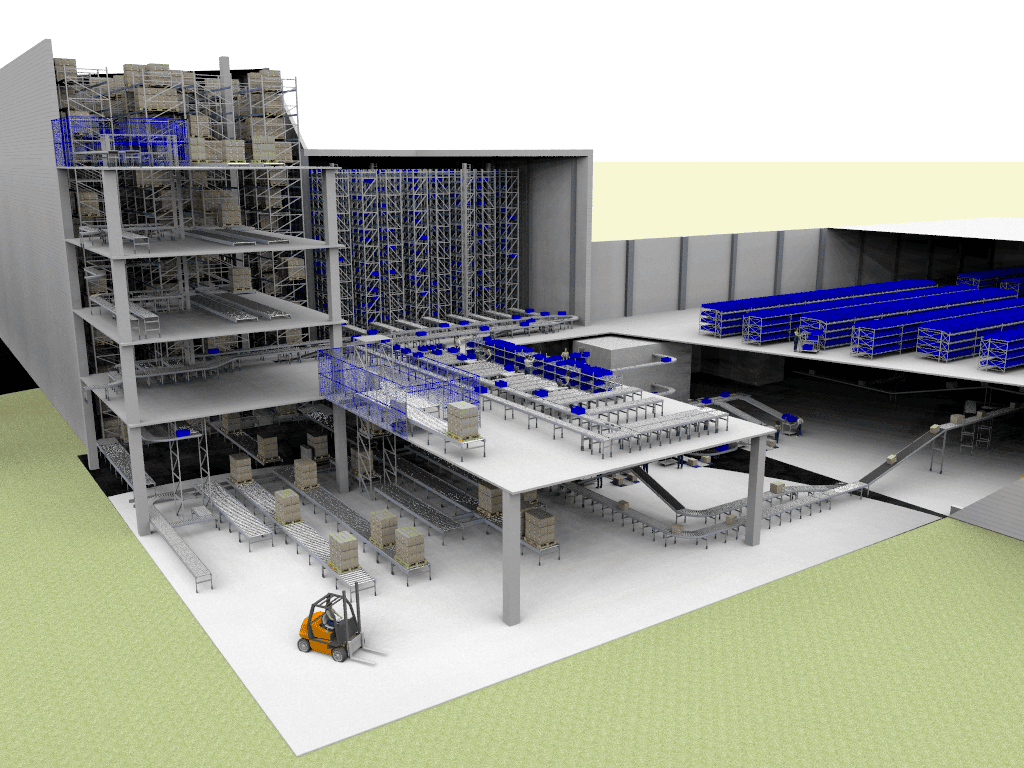

Moving images say more than plans

An impressive 3D animation makes it much easier to understand planned systems. Instead of having to rely solely on technical drawings or 2D plans, you can see the system in motion: machines are working, conveyor technology is transporting containers and pallets, forklifts are moving across the layout. This visualisation conveys an intuitive sense of space and improves communication with project participants and decision-makers.

Immerse yourself in the virtual world with VR glasses

The use of modern VR glasses makes it possible to virtually walk through planned plant rooms. The immersive display not only offers a spatial experience, but also allows realistic testing and operation of individual elements. Workstations such as assembly or picking stations can be experienced and evaluated directly – before a single handshake has taken place in the real world.

Interactive simulation instead of static models

A key advantage of virtual simulation is the possibility of interaction: users can interact with the system and test workflows, for example. This allows ergonomics, cycle times and material flows to be analysed as early as the planning phase. The insights gained are then directly incorporated into the optimisation process.

Efficient testing, rapid improvement

Adjustments to the virtual model can be made in no time at all – unlike physical prototypes, where changes involve considerable effort. Simulation also allows realistic load scenarios to be imported in order to analyse the effects on the overall system and identify bottlenecks at an early stage.

Future-proof thanks to digital twins and AI

Current developments show that combining VR technology with digital twins and artificial intelligence opens up further potential. It supports data-driven decisions and increases sustainability in production. As a result, 3D animation has long been more than just a planning tool – it is a strategic instrument on the road to the smart factory.