Peiner Träger GmbH uses simulation for optimization of scrap logistics

Peiner Träger GmbH, a subsidiary of Salzgitter AG, can look back on more than 140 years of tradition in steel production. Peiner Träger GmbH supplies a comprehensive range of support and support profiles for the construction industry manufactured on state-of-the-art systems. Within the framework of efficiency measures, Peiner Träger GmbH hoped to achieve cost savings in scrap logistics using simulation.

Assignment

- optimization of rail logistics for scrap delivery to a steel mill

- saving cars by reducing the number of “rolling” stocks

- determination of savings potential by combining scrap types

Goals

- determination of effort drivers

- securing concepts for cost reduction

- stock dimensioning in the tracks

- reduction of cycle times

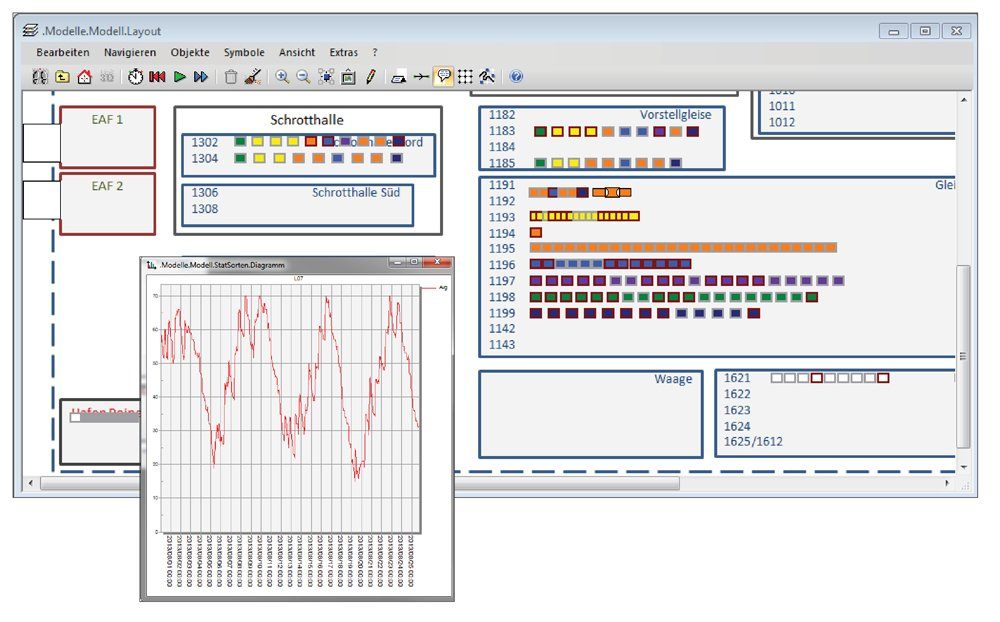

Functionality (software: plant simulation)

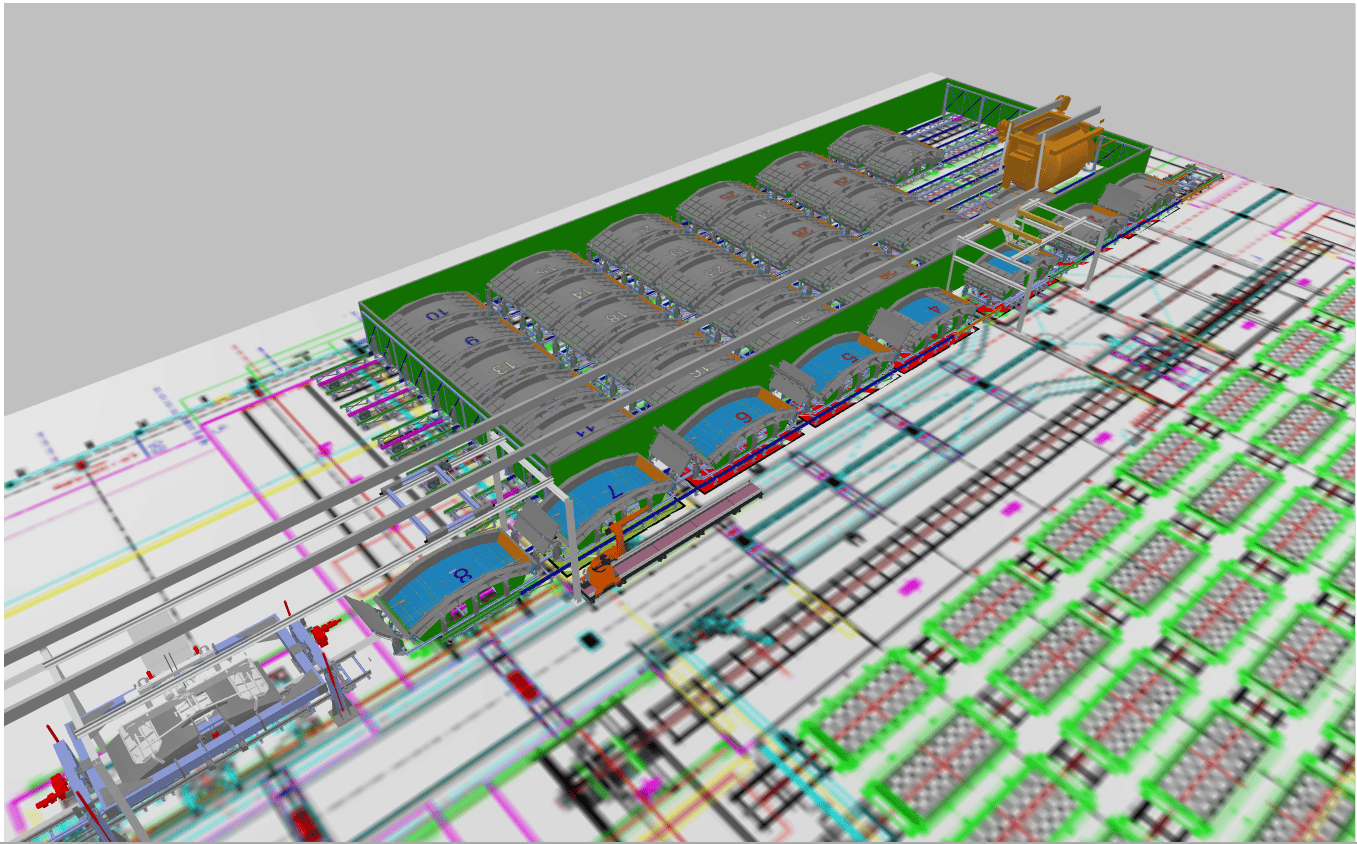

- illustration of the railway infrastructure

- activity profiles of the marshalling team

- compilation of activities through activity units

- disposition of scrap cars to sources

- import and export of Scenarios

Results/ benefits

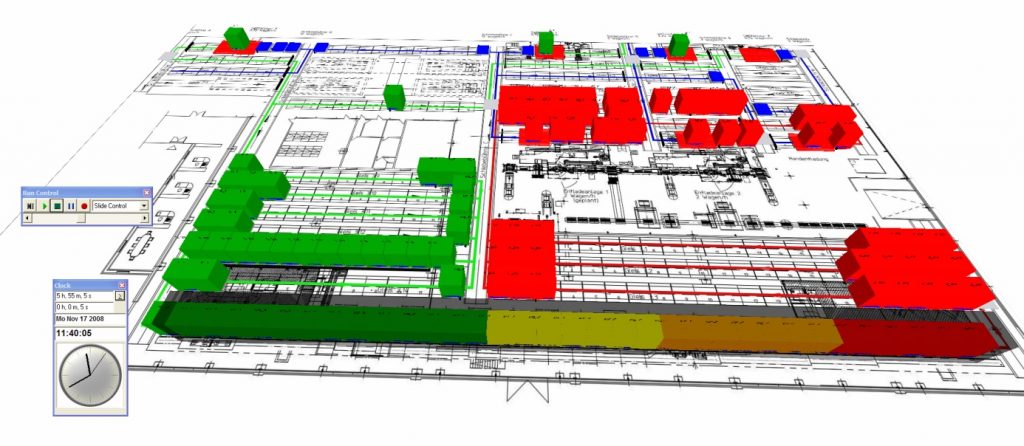

- assessment of different working time models on holdings

- visualization of effort drivers

- optimization of disposition an marshalling rules