Power & Free conveyor technology for a supplier (automotive)

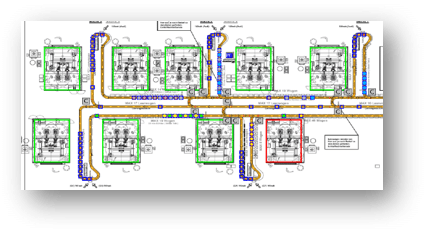

In the course of planning for the production of a complex component, a renowned German supplier of vehicle components in the cockpit area invited tenders for a Power and Free system. In order to be able to evaluate the performance of the technical component itself and the offer of the P&F supplier, the customer commissioned SimPlan to create a simulation model.

Here, the plant supplier provided all the necessary information about the P&F plant (chains, driver spacing, points, etc.). The customer himself provided the information on the supply and disposal systems.

In this case, the simulation model was also used to develop various control strategies (e.g. colour sorting storage), which were used by the P&F supplier as a blueprint for implementation in the real system.

The model could also be used for internal communication with the customer in order to coordinate the requirements of production, planning and logistics.

- Safeguarding supplier planning: identifying and eliminating bottlenecks.

- Development of a control system for a color sorting store.

- Detailed simulation of the specific characteristics of Power & Free conveyor technology:

Stopper, chain speed, driver spacing, behavior at switches, etc. - Variable switching on and off of production equipment for different volume scenarios

- Multiple layout improvements and revisions.

- Validated strategy for memory control.

- Determination of the system’s marginal performance at high rework rates Targets for production.

- Ideal communication platform for exchange between planning department and production.