Digital validation of output and cycle times in photovoltaic manufacturing

The simulation of complex production systems has become increasingly important in the photovoltaic industry. It is now used throughout the entire value chain, particularly for analysing plant concepts in terms of output and overall availability.

Objective of the simulation study

Reis Robotics develops manufacturing systems for photovoltaic modules. Simulation was used in the early planning phase to validate the system concept with regard to the required output and to identify bottlenecks at an early stage.

Production structure and process

The system under consideration manufactures a variant of photovoltaic modules. The central production steps are:

- Interconnection: Solar cells are first connected to strings and then to matrices.

- Lamination: The matrices are covered with film and placed in laminating ovens. There is a time-critical limit between the application of the film and the start of the lamination process.

- End of Line (EOL): The finished modules are framed and tested for functionality.

Methodology and simulation environment

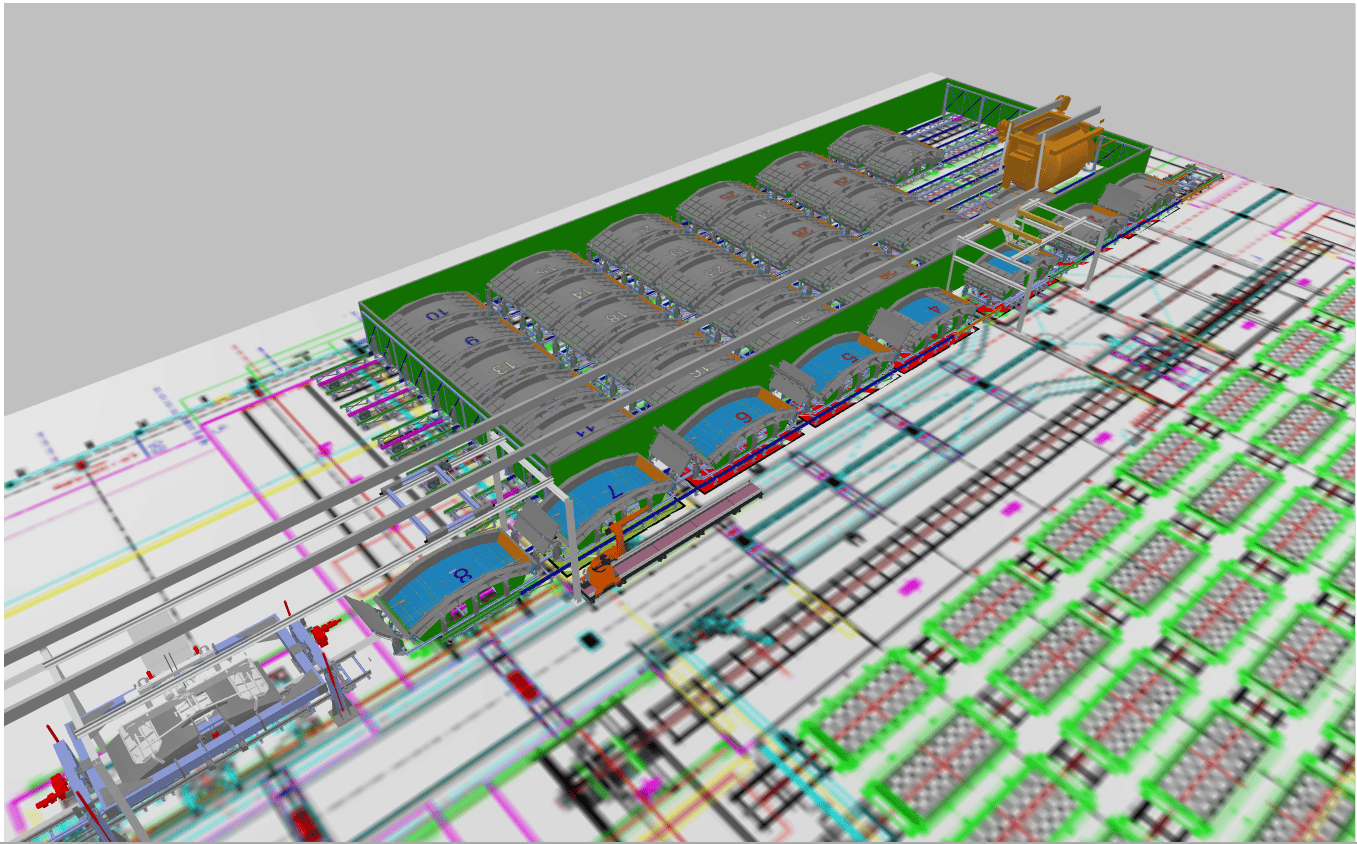

The SimPlan Solar Building Kit was used for modelling – a specially developed module package that maps the typical processes of module production, including conveyor technology and stations. The model was built based on the layout, i.e. conveyor lengths and elements were taken directly from CAD data.

Database and evaluations

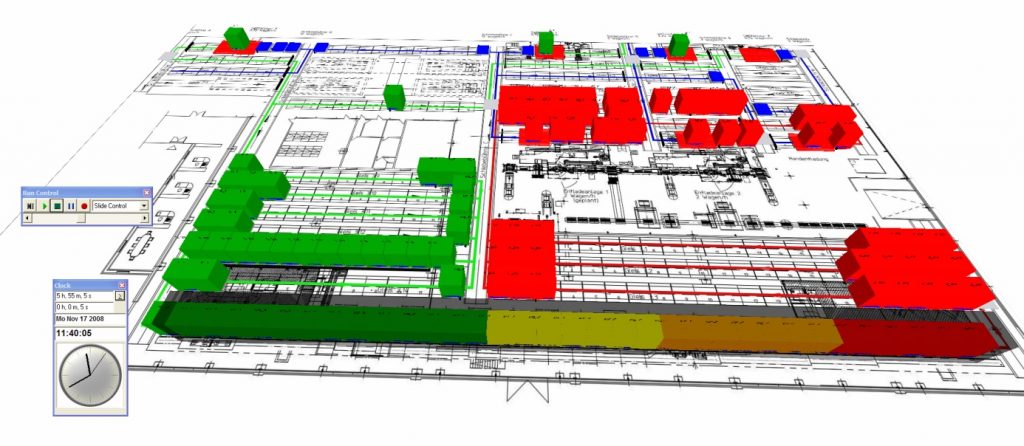

The input data was provided via a structured Excel database. This enabled the parameters to be automatically imported and transferred to the model modules. The hourly throughput of the plant was the key parameter for the evaluation. This was compared with three target throughputs derived from:

- the planned cycle time in undisturbed operation and

- the expected minimum availability of the entire plant

.Analysis of critical stations

Another focus was on investigating the cycle times of critical process stations. The aim was to evaluate their influence on the overall throughput and to identify potential bottlenecks in the plant layout at an early stage.