Würth Elektronik eiSos – SimPath model extension

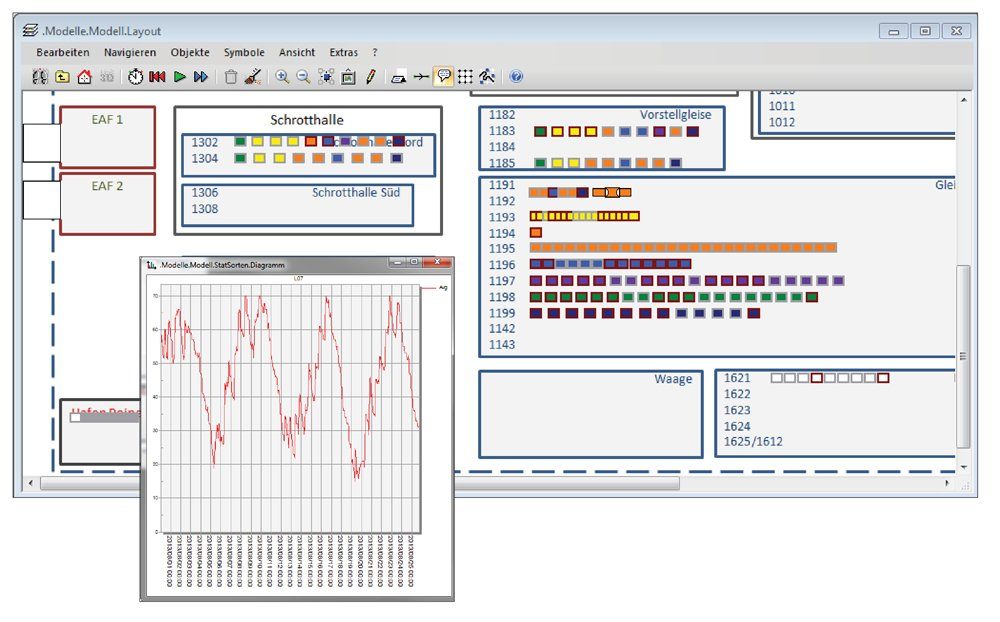

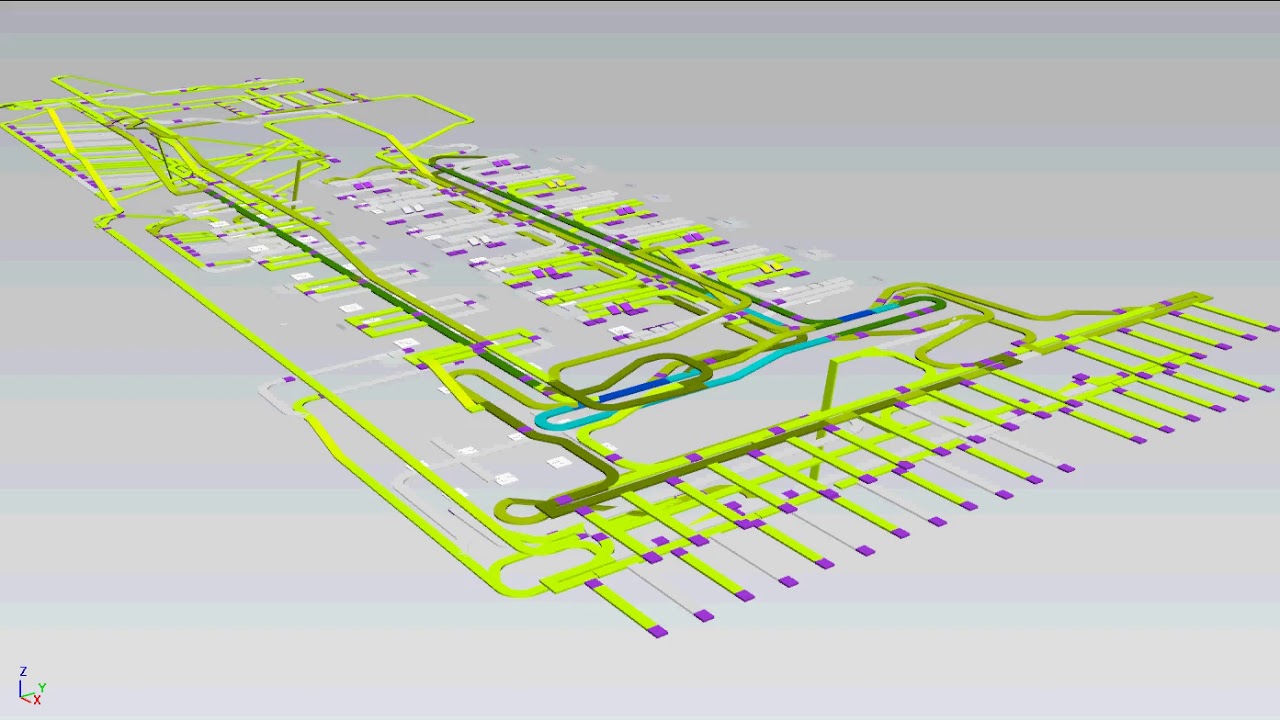

SimPath is a tool for continuous observation and optimization of real systems. Especially in complex systems, a lot of information accumulates in the form of counting point data, which, however, can only be analyzed in a very abstract way. SimPath provides a process mining tool for logistic systems and makes it possible to analyze and visualize the material flow in detail and to provide a corresponding dynamic key figure system. This can be used for real and simulation data as well as for planning data. The SimPath Library makes it easy to set up a material handling system in 3D and to transfer the data quickly.

As part of the expansion of the logistics system of Würth eiSos in Waldenburg, Germany, we extended an existing SimPath model for visualization and analysis of the material flow. Würth Elektronik eiSos is one of the leading manufacturers of electronic and electromechanical components in Europe.

All new plant areas (shuttle lanes, picking stations, packing stations and shipping area) were integrated into the existing model and the corresponding communication points (reporting points) were taken into account. The analyses were able to uncover further problems in the current plant control system.

Thanks to the reports created with SimPath on the basis of the metering point information, the project partners involved now have the possibility to specifically track the problems in order to work out solutions in a targeted manner. Currently, the analyses are carried out within the framework of WebMeetings. Subsequently, the SimPath model will be connected directly to the production system so that online analyses can be carried out on-the-fly in the future.

The video shows an example of the development of the conveyor load over the time axis (hourly grid). Each color represents the magnitude of the volume flow on the corresponding line section in this hour.