Simulation of a meat warehouse for EDEKA Südwest Fleisch GmbH

EDEKA Südwest Fleisch GmbH has built a new, highly efficient meat processing plant in Rheinstetten (Baden-Württemberg). Since mid-2011, top-quality sausage and meat products have been produced there and delivered to more than 1,250 EDEKA Südwest stores.

Project objectives and challenges

As a system supplier, Vanderlande Industries GmbH from Mönchengladbach was commissioned to implement the logistics system between production and dispatch. To safeguard the planning and investment, EDEKA Südwest Fleisch commissioned SimPlan Integrations GmbH in Witten in 2009 to map the entire material flow in a simulation model.

- Highly dynamic 20-lane shuttle system as replenishment and buffer warehouse

- Sequence-accurate retrieval of > 7,000 loading units per hour

- Sequence compliance for E1/E2 containers and cartons

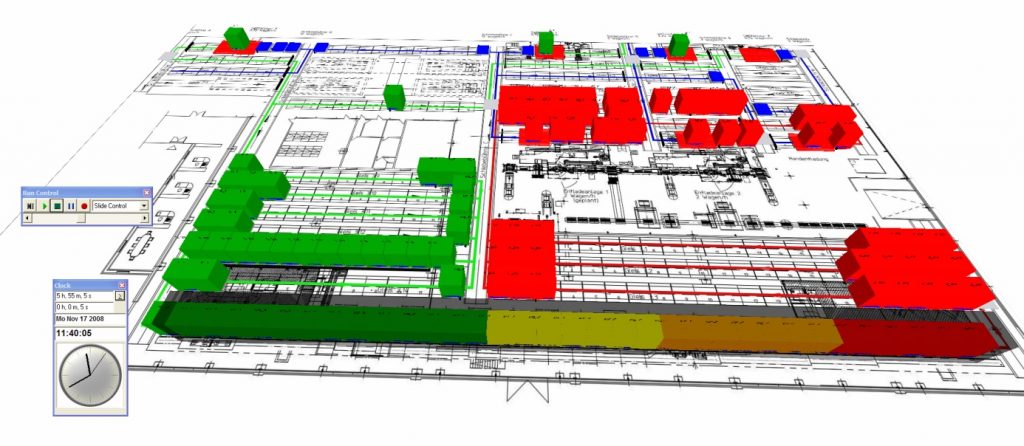

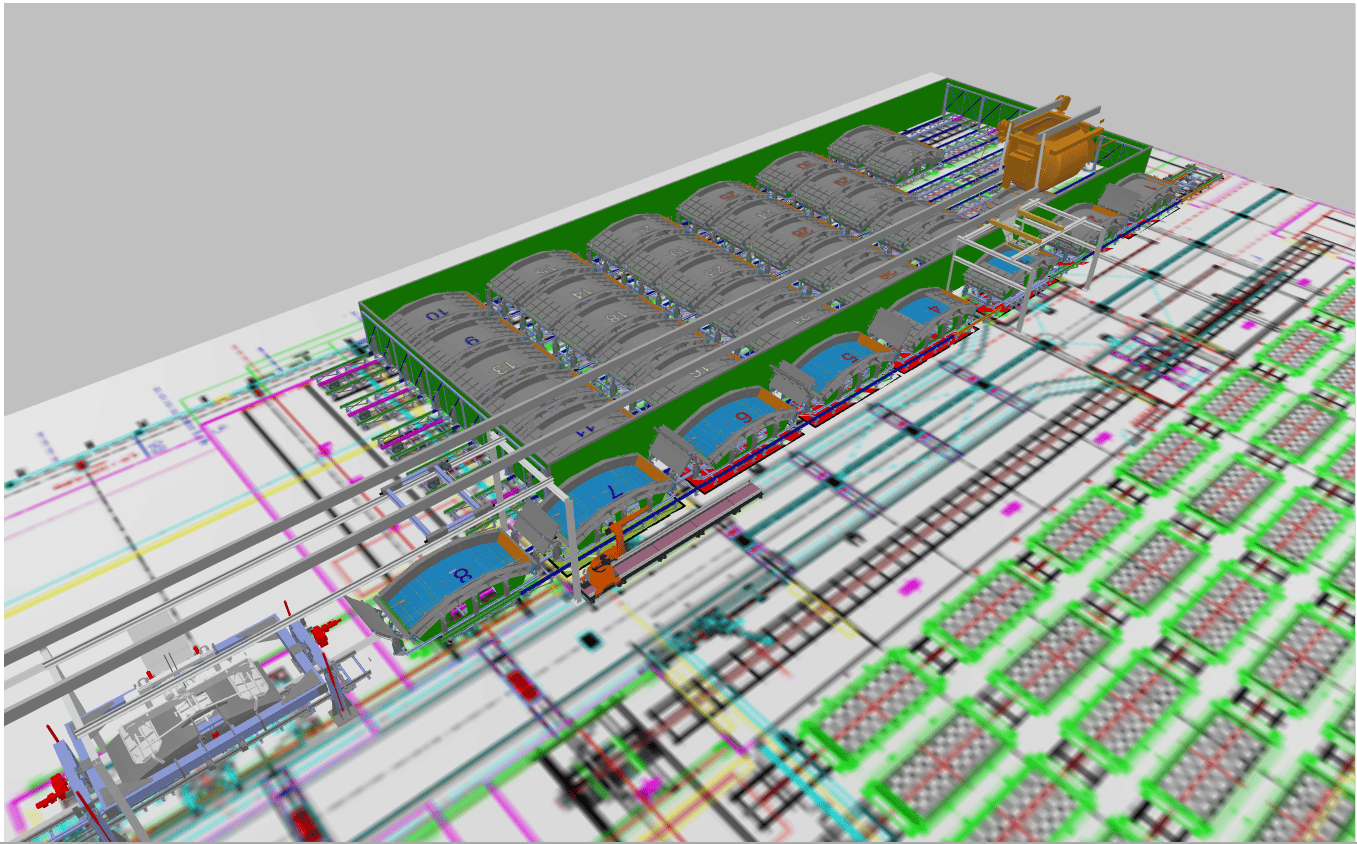

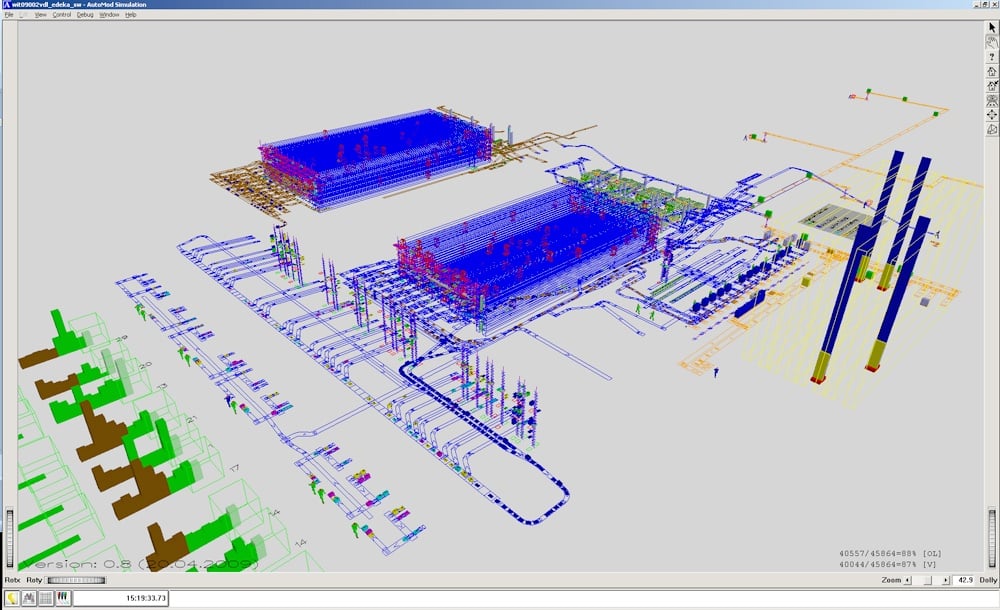

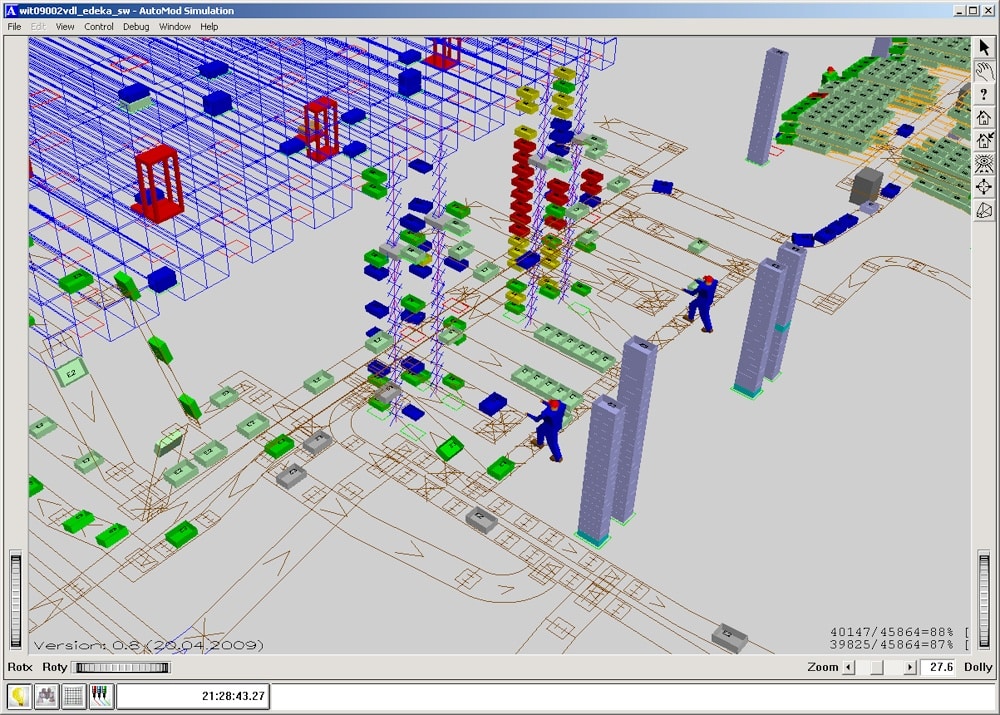

Simulation approach with AutoMod

The powerful AutoMod simulation tool was used to model all trades in technical and strategic detail:

- High-bay pallet warehouse with pre-zone and 10 depalletising stations

- 20-aisle shuttle system with double-lift principle and 140 shuttles

- Connecting conveyor technology over more than 3,000 m

- Picking area with 19 manual and 2 automatic ‘goods-to-man’ stations

- Empty container cycle and dispatch system with sorter, sequencing buffers and roller loading stations

Detailed process modelling

Based on projected order data (2009) and initial stock levels in the shuttle block, all logistical processes were simulated:

- Production → Storage → Inventory management

- Reservation → Order picking → Shipping

- Replenishment movements HRL → Shuttle block → Order picking stations

Precise tracking of each unit ensures realistic evaluations and reliable recommendations.

Results & practical application

The simulation delivered:

- Optimal distribution strategies for articles and customer LE on the shuttles

- Performance profiles to avoid under- or oversizing

- Sequence strategies for reliable trolley loading

All strategies developed were documented and directly implemented in practice. Since commissioning, the system has been running precisely according to the simulation results – proof of the high quality of the model and the benefits of simulation studies for complex logistics solutions.