BAYER uses simulation to optimize production line material flows

In recent years, Bayer AG has introduced simulation for decision support in planning in the Crop Science division. Since 2019, SimPlan AG has been supporting the mapping of the various production lines in simulation models and the investigation of various planning scenarios as part of the Virtual Factory project.

Simulation is used for investigations and optimizations of the material flows of the production lines of various sites. The main issues are:

- Determination of bottlenecks in the production flow,

- Identification of improvement potentials,

- Investigation of shift models or personnel scheduling,

- support in the planning of production orders or in the formation of campaigns.

The concrete focal points of the investigations differ for the locations. This has a direct impact on the requirements for the level of detail of the modeling. At individual sites, more in-depth use of the models as onsite use is also planned or has already been implemented. In onsite use, non-simulation experts at the sites use the simulation solution created to support them in their daily production control or in planning campaigns.

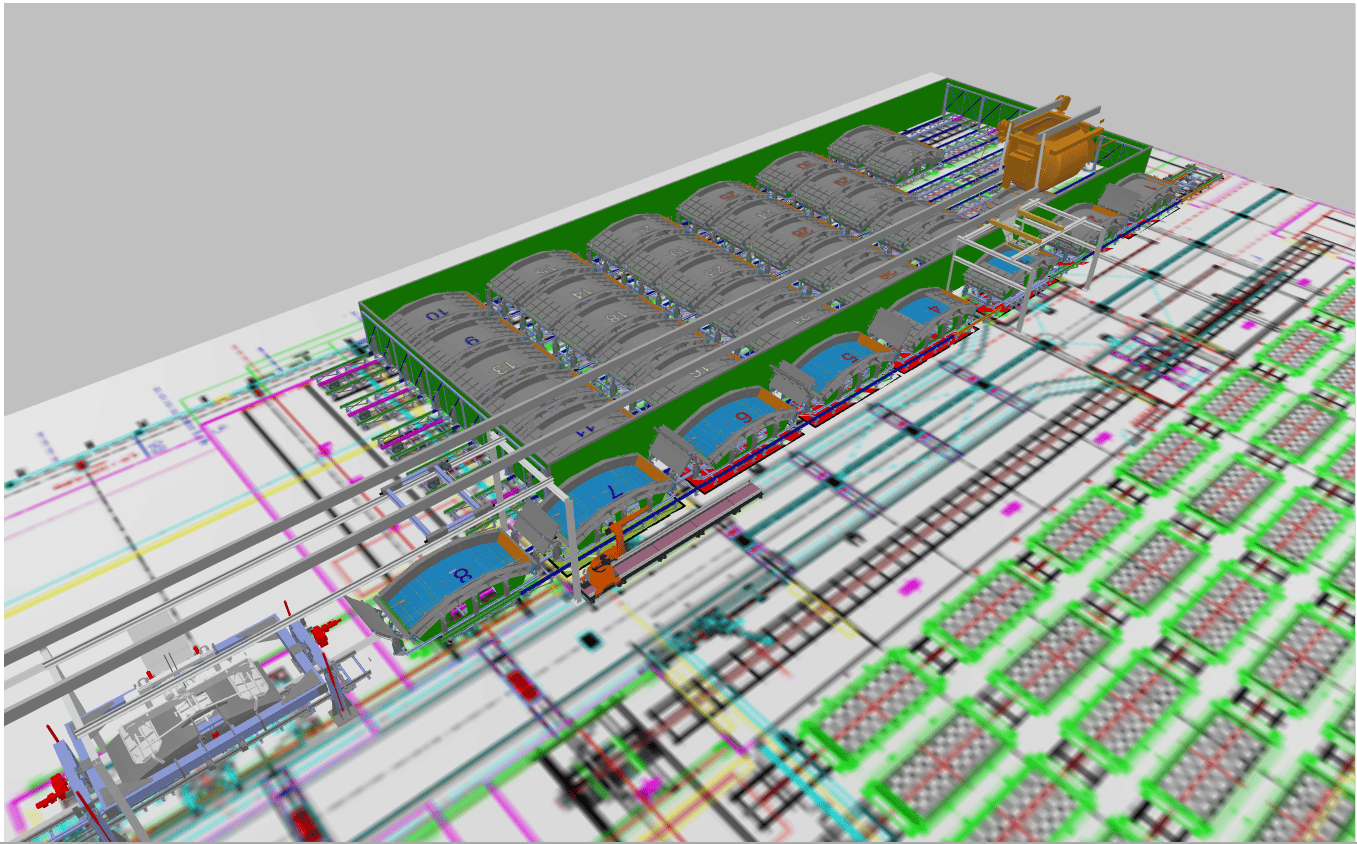

The basic processes in the Crop Science division are formulation, the precise and homogeneous mixing of different substances, and filling or packaging. The central material flow objects of formulation are the containers for mixing the various components and pre-milling, as well as the mills for the actual formulation process.

The basic structure of the lines and the operations for production are always identical, but differ in detail at the various sites or for different products. This means, above all, that a detailed process analysis is always necessary in order to build the models correctly.

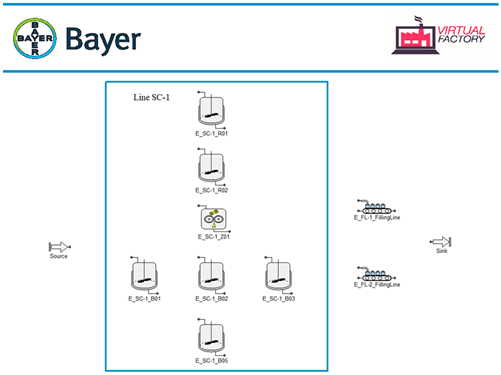

We use the simulation tool INOSIM for modeling, which was developed especially for the process industry. The structure of the lines, i.e. the different containers that make up the line, is described by the layout. These containers can be used to execute the manufacturing steps or for buffering.

The processes for the production of the final product as well as the material flow are described by so-called recipes. A recipe includes all operations that are necessary for the production of a product. These operations can take place within a container or be transfers between containers. For example, such a recipe includes the operations for filling the individual raw materials into a mixer, mixing these raw materials in this mixer and transferring the mixture to the next container.

Typical tools for evaluation are Gantt charts showing the executed orders in the containers of the lines and the filling level progressions. These representations are used to identify and, if possible, minimize capacity losses due to waiting times.

The projects at the first sites have already been largely completed or the models handed over for onsite use. As a rule, initial scenarios were already examined in the project phase after validation of the models. For example, different shift scenarios were compared here to determine their impact on the execution of orders and the throughput of the lines.

We used the findings from these projects to develop a standard together with Bayer and INOSIM, on the basis of which all further models will be built. To this end, templates for layouts and recipe structures of the formulation or filling lines were provided, which serve as a starting point for the modeling. In this way, the basic structure of the models can be built up more quickly and efficiently in the future. Only for specific features of the individual lines fall.

We used the findings from these projects to develop a standard together with Bayer and INOSIM, on the basis of which all further models will be built. To this end, templates were provided for layouts and recipe structures of the formulation and filling lines, which serve as a starting point for modeling. In this way, the basic structure of the models can be built up more quickly and efficiently in the future. Only the specific features of the individual lines will require further implementation work.

In parallel to project execution, generally applicable training documents were developed for onsite use. In this way, it is possible to familiarize the contact persons at the sites with the simulation procedure at a very early stage and to introduce the software used. The training documents facilitate communication within the project team, consisting of simulation experts and technical personnel at the production site. They serve to communicate the data requirements of the simulation as well as realistic expectations of the results that can be achieved with the help of the simulation. It has been shown that a realistic assessment of the effort required to obtain the necessary input data as well as the expected results of the simulation study are critical to the success of individual projects.

Other projects

The basic processes in the Crop Science division are formulation, the precise and homogeneous mixing of different substances, and filling or packaging. The central material flow objects of formulation are the containers for mixing the various components and pre-milling, as well as the mills for the actual formulation process.

The basic structure of the lines and the operations for production are always identical, but differ in detail at the various sites or for different products. This means, above all, that a detailed process analysis is always necessary in order to build the models correctly.

We use the simulation tool INOSIM for modeling, which was developed especially for the process industry. The structure of the lines, i.e. the different containers that make up the line, is described by the layout. These containers can be used to execute the manufacturing steps or for buffering.

The processes for the production of the final product as well as the material flow are described by so-called recipes. A recipe includes all operations that are necessary for the production of a product. These operations can take place within a container or be transfers between containers. For example, such a recipe includes the operations for filling the individual raw materials into a mixer, mixing these raw materials in this mixer and transferring the mixture to the next container.

Typisches Instrument für die Auswertung sind Gantt-Charts mit Darstellung der ausgeführten Aufträge in den Behältern der Linien und der Füllstandsverläufe. Diese Darstellungen werden genutzt, um Kapazitätsverluste aufgrund von Wartezeiten zu identifizieren und möglichst zu minimieren.

The projects at the first sites have already been largely completed or the models have been handed over for onsite use. As a rule, initial scenarios were already examined in the project phase after validation of the models. For example, different shift scenarios were compared here to determine their impact on job execution and line throughput.

We used the findings from these projects to develop a standard together with Bayer and INOSIM, on the basis of which all further models will be built. To this end, templates for layouts and recipe structures of the formulation or filling lines were provided, which serve as a starting point for the modeling. In this way, the basic structure of the models can be built up more quickly and efficiently in the future. Only the specific features of the individual lines will require further implementation work.

In parallel to project execution, generally applicable training documents were developed for onsite use. In this way, it is possible to familiarize the contact persons at the sites with the simulation procedure at a very early stage and to introduce the software used. The training documents facilitate communication within the project team, consisting of simulation experts and technical personnel at the production site. They serve to communicate the data requirements of the simulation as well as realistic expectations of the results that can be achieved with the help of the simulation. It has been shown that a realistic assessment of the effort required to obtain the necessary input data as well as the expected results of the simulation study are crucial for the success of the individual projects.